1.CNC Machined from Solid Metal: Carved from a single billet of aerospace aluminum for supreme detail and zero porosity.

2.Superior Detail & Sharpness: Achieves crisper edges and more complex geometries than cast or printed models.

3.Exceptional Weight & Stability: Has a premium, substantial heft and a rock-solid foundation.

4 Flawless Surface Finish: Polished, brushed, or anodized to a perfect, gallery-ready finish without layer lines.

5. Masterful Hand-Painting: Each piece is individually hand-finished by expert artists for unparalleled realism.

6.Highly Limited Edition: A scarce, numbered collectible built to last for generations and appreciate in value.

1.Ultralight & Compact Design

Engineered with advanced materials to minimize weight without sacrificing strength.

Nestable or collapsible design drastically reduces pack size, freeing up crucial space in your backpack.

2.Uncompromising Durability

Crafted from shatterproof materials (e.g., premium polypropylene, titanium) that withstand drops, impacts, and rough handling.

Resilient against cracks and deformation, built to last for countless adventures.

3.Effortless Cleaning & Hygiene

Ultra-smooth, non-porous surface prevents food residue and odors from sticking.

Most models are dishwasher-safe for ultimate convenience after a long day outdoors

1.Optimized Airflow: Strategically designed to maximize ventilation, effectively reducing condensation and ensuring a comfortable interior climate.

2.Superior Weather Protection: Engineered with precision seals and waterproof materials to keep rain, wind, and dust out.

3.Durable & Lightweight Construction: Built with high-strength, low-weight materials for reliable performance without adding bulk.

4.Intuitive & Quiet Operation: Features like magnetic closures or smooth zippers allow for easy, silent adjustment.

5.Tailored to Your Design: Fully customizable in size, shape, color, and functionality to perfectly integrate with your tent's architecture.

1. Precise Fit & Ergonomic Optimization

3D design enables ultra-accurate modeling of outdoor gear (e.g., backpacks, tents, hiking boots) based on human body data or real-world usage scenarios. This ensures a snug, ergonomic fit—for example, 3D-modeled backpack straps that conform to the spine to reduce shoulder pressure, or tent interiors tailored to maximize movement space without wasting material. It eliminates the "one-size-fits-all" flaws of traditional 2D-designed gear, enhancing comfort during long outdoor activities.

Visualized Pre-Use Experience

2.Before physical production, 3D design creates realistic, interactive digital prototypes of outdoor products. Customers can view 360° renders of gear (e.g., a tent’s setup process, a jacket’s zipper and pocket details) online, or even use AR to "place" the product in their actual camping environment. This bridges the gap between online shopping and in-person inspection, helping users make more confident purchase decisions without guessing product size, shape, or functionality.

Functional Efficiency & Material Savings

3. 3D design allows engineers to simulate real-world conditions (e.g., wind resistance for tents, water flow for backpack rain covers) and optimize gear structure digitally. For instance, a 3D-modeled camping chair can be adjusted to distribute weight evenly across the frame, improving durability while reducing unnecessary material use. This not only boosts the gear’s performance (e.g., better windproofing, lighter weight) but also minimizes waste in production, aligning with eco-friendly outdoor values.

Customization Flexibility

4.3D design simplifies personalized adjustments for outdoor gear. Whether it’s modifying the size of a tent’s vestibule, adding extra pockets to a hiking pack, or changing the color of a sleeping bag’s lining, 3D models can be tweaked quickly without rebuilding the entire design from scratch. This caters to diverse user needs—such as family campers needing more space or solo hikers prioritizing compactness—making gear more tailored to individual adventures.

Faster Innovation & Iteration

1. Superior Material & Craftsmanship:

Crafted from premium polyresin for exceptional weight, durability, and a cold, stone-like feel that signifies quality.

Meticulous hand-casting and assembly ensure each piece is a unique work of art, not just a mass-produced toy.

2. Exquisite Detail & Realism:

Breathtaking attention to detail, from intricate costume textures and armor weathering to lifelike skin pores and hair strands.

Features dynamic posing and authentic character likeness, perfectly capturing the essence of the original IP.

3. High-Definition Paint Application:

Expertly hand-painted with precision airbrushing and meticulous wash techniques for unparalleled depth and realism.

Features advanced painting effects such as subtle gradients, metallic finishes, and realistic battle damage for a truly immersive display.

4. Exclusive & Collectible:

Produced in a strictly limited edition (e.g., [Number] pieces worldwide), ensuring exclusivity and long-term value for collectors.

Each piece includes a unique serial number and a certificate of authenticity, guaranteeing its genuine origin.

5. Impressive Presence & Display Value:

Substantial size and significant weight command attention, making it the definitive centerpiece of any collection or display.

Often includes a themed base or diorama that enhances the narrative and visual impact of the character.

6. For the True Enthusiast:

The ultimate premium collectible for discerning fans and serious collectors, representing the highest tier of merchandise available.

A must-have grail item that showcases deep passion for the character and franchise

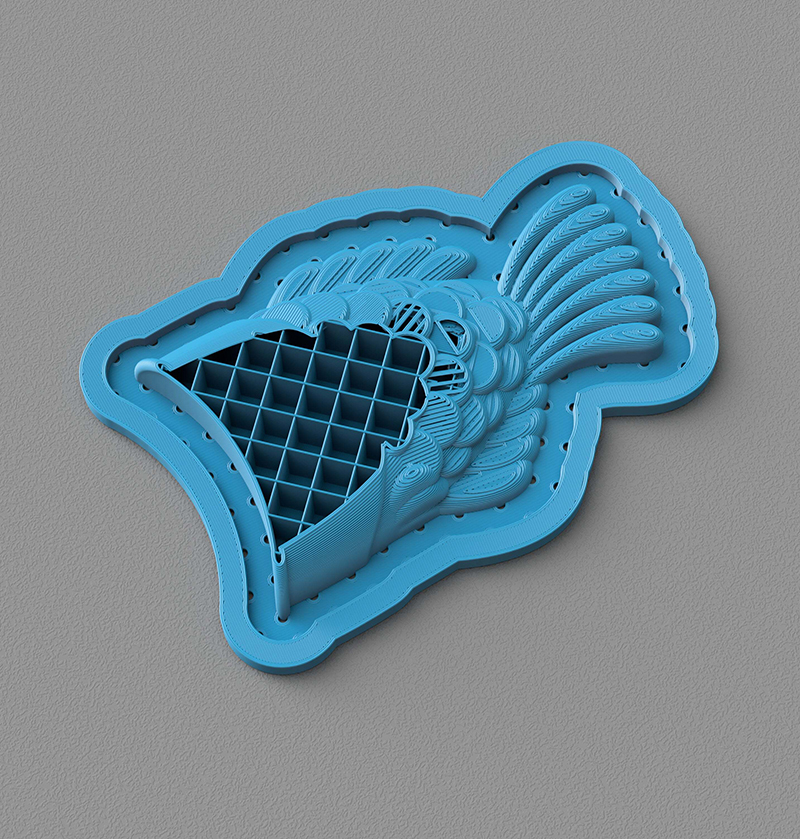

1.Superior Weather & Impact Resistance

Engineered to endure harsh outdoor conditions—resists cracking, UV damage, and temperature swings.

2.High Flexibility & Tear Resistance

Stretches without losing shape and withstands repeated use, ideal for rugged outdoor crafting and DIY projects.

3.Eco-Friendly & Reusable

Made from durable, non-toxic rubber—perfect for sustainable outdoor living and reducing waste.

4.Perfect for Outdoor Creations

Design custom garden decorations, pathway markers, bird feeders, and camping accessories with ease.

5.Easy Demolding & Sharp Details

Ensures clean releases and preserves fine patterns every time, even in humid or variable outdoor environments.

6.Compact & Portable

Lightweight and easy to pack—take your molding projects anywhere, from the backyard to the trails.

1.Built for the Elements: Superior Weather & UV Resistance: We specialize in molding with outdoor-grade elastomers like EPDM and Silicone, which provide exceptional resistance to weathering, ozone, UV degradation, and extreme temperature swings, ensuring your gear won't fail in the sun, snow, or rain.

2.Uncompromising Sealing for Waterproof Integrity: Create reliable environmental seals for critical outdoor applications. Our process produces waterproof gaskets for hatches, O-rings for hydration systems, and seals for sensor housings with consistent density to keep moisture, dust, and debris out.

3.Cost-Effective for Durable Goods Production: While ideal for prototyping, compression molding becomes highly economical for medium to high-volume production runs of durable components, from kayak hatches and dive computer cases to batches of custom O-rings for repair kits.

4.Ergonomic & Secure Grip Solutions: Mold comfortable, non-slip grips with specific Shore A hardness values for tools, knife handles, trekking poles, and watercraft paddles. The process allows for overmolding on substrates for superior adhesion and durability.

1.Unmatched Durability for Harsh Environments

Engineered for Impact Resistance: Manufactured from high-grade, UV-stabilized polymers to withstand brutal impacts, drops, and abrasion from rock, ice, and trail debris.

2.Weatherproof & Corrosion-Resistant: Superior material formulation ensures complete resistance to moisture, salt spray, extreme temperature swings, and UV radiation, preventing fading, brittleness, and corrosion.

3. Lightweight & Ergonomic Design for Peak Performance

Precision-Engineered Lightweighting: Advanced mold flow analysis allows for complex geometries that maximize strength while minimizing weight, reducing fatigue on long treks and climbs.

All-Terrain Grip & Handling: Textured, over-molded surfaces provide a secure, non-slip grip even with wet hands or gloves, ensuring total control in rain, snow, or mud.

4. Superior Structural Integrity & Reliability

Seamless, Monolithic Construction: Injection molding creates a single, unified part with no weak seams or joints, guaranteeing exceptional structural integrity under load and stress.

Rigorous Quality Assurance: Every component is tested to perform flawlessly across an extreme temperature range (-40°F to 220°F / -40°C to 104°C), ensuring reliability from desert to alpine environments.

1. Ultimate Customization & Personalization

Tailored Ergonomics: Products are printed to fit your body's unique contours perfectly, enhancing comfort and performance.

Modular Design: Customize and print specific modules or attachments to adapt your gear for different activities.

Personalized Aesthetics: Incorporate your name, logos, or unique designs to make your gear truly one-of-a-kind.

2. Lightweight & Topology-Optimized Structures

Strength-to-Weight Mastery: Advanced software algorithms design structures that use the minimum material necessary to achieve maximum strength, significantly reducing weight.

Conscious Packing: Lighter and often more compact gear lightens your load and saves precious pack space.

3. Unmatched Design Freedom & Complexity

Integrated Functionality: Print complex mechanisms, hinges, and interlocking parts as a single, seamless piece, eliminating assembly and potential failure points.

Organic, Nature-Inspired Forms: Create biomimetic structures (like honeycombs or bone lattices) that are impossible to produce with traditional manufacturing, resulting in superior strength and unique aesthetics.

1.Tailored Fit for Individual Comfort:Precisely customized based on your height, arm length, and grip preference. Whether you have a shorter stature or larger hand size, the trekking poles can be adjusted to a length and grip diameter that fits you perfectly, eliminating discomfort from ill-fitting standard poles during long hikes.

2.Personalized Aesthetic & Identity:Support full customization of appearance elements, including color matching (such as matching your outdoor gear color scheme), laser engraving (of your name, favorite outdoor motto, or unique pattern), and even custom grip textures. Make your trekking poles a distinctive symbol of your outdoor style.

3.Customized Functional Upgrades:Choose functional components based on your hiking scenarios. For example, if you often trek on rocky terrain, you can select extra-durable tungsten carbide tips; if you frequently hike in snowy areas, you can match custom-sized snow baskets. You can also opt for detachable or foldable designs according to your storage and carrying needs.

Premium Material Selection for Specific Needs:Pick materials tailored to your usage requirements and budget. If you pursue ultra-lightweight performance for high-altitude hikes, you can choose high-grade carbon fiber; if you need more cost-effective and impact-resistant options for daily suburban treks, customized aluminum alloy poles are available. All materials undergo strict quality testing to ensure reliability.

4.Ergonomic Custom Grip Design:Beyond adjusting grip size, the grip shape can be customized to fit the natural curve of your palm. For instance, if you tend to hold the pole with a forefinger-led grip, the grip can be designed with a slight indentation in the forefinger area, reducing hand fatigue and enhancing grip stability during long-time use.

1. Exceptionally Low Tooling & Startup Costs

Compared to other molding processes like injection molding, vacuum forming uses simple, single-sided molds. These molds can be crafted from inexpensive materials like wood, high-density urethane (HDU), or 3D-printed plastic, drastically reducing initial investment and making it ideal for prototyping and short production runs.

2. Rapid Prototyping and Short Lead Times

The simplicity of the process allows for incredibly fast transition from design concept to tangible part. Molds can be produced and modified quickly, enabling rapid iteration, design validation, and faster time-to-market for new products.

3. Unmatched Capacity for Large Parts

Vacuum forming is one of the most economical methods for producing very large plastic components. It is capable of creating massive parts—such as vehicle body panels, bathtubs, kayaks, and industrial machine covers—that would be prohibitively expensive or technically challenging to manufacture with other processes.

4. Superior Material and Finish Flexibility

Manufacturers can choose from a vast library of thermoplastic sheets available in an extensive range of colors, textures, thicknesses, and material properties (e.g., ABS for strength, PETG for clarity, HIPS for cost-effectiveness). Parts can be formed with integrated finishes like gloss, matte, texture, or metallic, often eliminating the need for post-processing painting.

5. Cost-Efficiency for Low to Medium Volume Production

For production batches ranging from a few dozen to several thousand units, vacuum forming offers an outstanding per-part cost advantage. The low maintenance of the molds and the efficient use of material make it the most economical choice for these volumes.

6. Durability and Structural Integrity

Vacuum-formed parts are typically single-piece constructions with no welded seams, resulting in high strength and excellent impact resistance. This makes them perfect for applications requiring robust and reliable packaging, protective covers, or durable exterior components.

In summary, the key highlights of vacuum forming are its low cost, speed for large parts, and exceptional flexibility, making it the premier choice for prototypes, large-scale components, and short- to medium-run production.

1.Frame-Matched Precise Fit:Tailored to the specific tube shape, diameter, and mounting hole spacing of your road bike frame (e.g., aero frames, round-tube frames, or specialty carbon frames). Ensures seamless integration with no awkward gaps or unstable mounting, avoiding the "one-size-fits-all" wobble that risks bottle spills during high-speed rides.

2.Personalized Aesthetic Coordination:Supports full visual customization to align with your bike’s style. Options include matching your frame’s paint color (with high-durability, weather-resistant coatings), adding custom laser engravings (e.g., your name, team logo, or lucky number), or choosing unique finishes (matte, glossy, or carbon fiber weave exposed) to make the cage a stylish extension of your bike.

3.Ride-Scenario Optimized Functionality:Customize features based on your riding habits. For long-distance gran fondos, opt for a deeper cage design to secure large-capacity bottles; for time trials or aero-focused rides, choose a low-profile, wind-resistant shape to minimize drag. You can also add anti-slip rubber inserts (custom-colored to match) for extra bottle retention on rough roads.

4.Material Customization for Performance & Preference:Select materials tailored to your needs—whether you prioritize ultra-lightweight performance (high-modulus carbon fiber for minimal weight), durability for daily training (anodized aluminum to resist scratches), or eco-friendliness (recycled composite materials). All materials are tested for road durability, ensuring they withstand vibration, weather, and repeated bottle insertion/removal.

Recommend

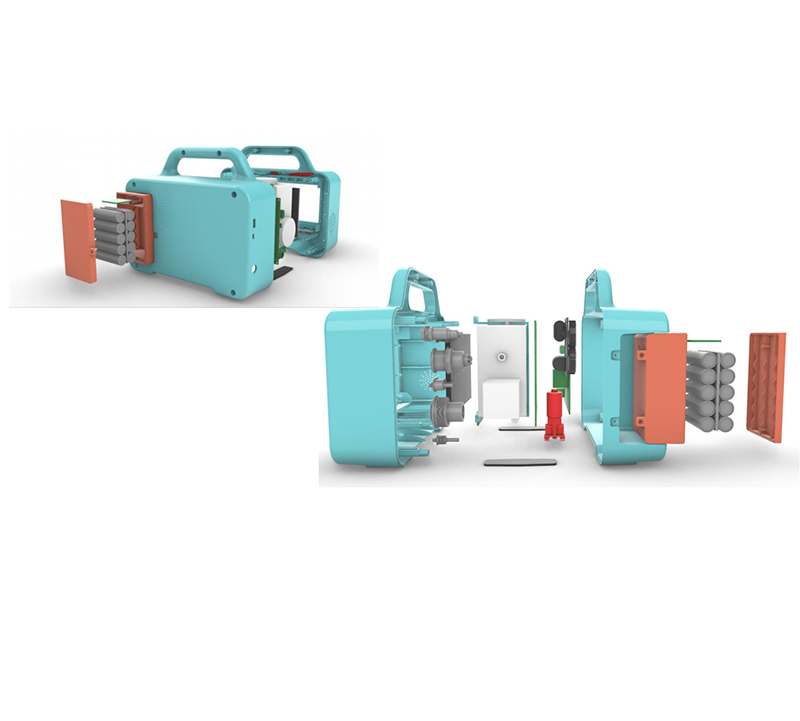

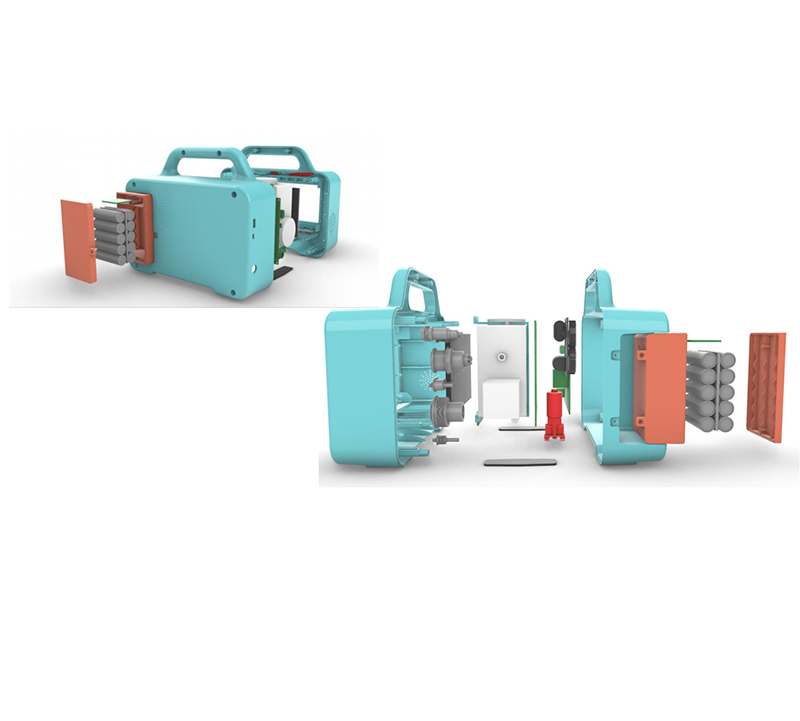

1.High Efficiency & Automation: Designed for fully automatic, high-speed cycling, significantly boosting production output and reducing labor costs.

2.Exceptional Durability: Manufactured from premium hardened steels, the mold ensures a long service life and consistent performance even under high-volume production.

3.Superior Surface Finish: The mold cavity is precision-polished or textured to produce stools with a flawless, high-quality aesthetic appearance right out of the machine.

4.Innovative Cooling System: An optimized cooling channel layout guarantees uniform and rapid part cooling, minimizing cycle times and preventing warpage for perfect dimensional stability.

1. Precise Fit & Ergonomic Optimization

3D design enables ultra-accurate modeling of outdoor gear (e.g., backpacks, tents, hiking boots) based on human body data or real-world usage scenarios. This ensures a snug, ergonomic fit—for example, 3D-modeled backpack straps that conform to the spine to reduce shoulder pressure, or tent interiors tailored to maximize movement space without wasting material. It eliminates the "one-size-fits-all" flaws of traditional 2D-designed gear, enhancing comfort during long outdoor activities.

Visualized Pre-Use Experience

2.Before physical production, 3D design creates realistic, interactive digital prototypes of outdoor products. Customers can view 360° renders of gear (e.g., a tent’s setup process, a jacket’s zipper and pocket details) online, or even use AR to "place" the product in their actual camping environment. This bridges the gap between online shopping and in-person inspection, helping users make more confident purchase decisions without guessing product size, shape, or functionality.

Functional Efficiency & Material Savings

3. 3D design allows engineers to simulate real-world conditions (e.g., wind resistance for tents, water flow for backpack rain covers) and optimize gear structure digitally. For instance, a 3D-modeled camping chair can be adjusted to distribute weight evenly across the frame, improving durability while reducing unnecessary material use. This not only boosts the gear’s performance (e.g., better windproofing, lighter weight) but also minimizes waste in production, aligning with eco-friendly outdoor values.

Customization Flexibility

4.3D design simplifies personalized adjustments for outdoor gear. Whether it’s modifying the size of a tent’s vestibule, adding extra pockets to a hiking pack, or changing the color of a sleeping bag’s lining, 3D models can be tweaked quickly without rebuilding the entire design from scratch. This caters to diverse user needs—such as family campers needing more space or solo hikers prioritizing compactness—making gear more tailored to individual adventures.

Faster Innovation & Iteration

1. Superior Material & Craftsmanship:

Crafted from premium polyresin for exceptional weight, durability, and a cold, stone-like feel that signifies quality.

Meticulous hand-casting and assembly ensure each piece is a unique work of art, not just a mass-produced toy.

2. Exquisite Detail & Realism:

Breathtaking attention to detail, from intricate costume textures and armor weathering to lifelike skin pores and hair strands.

Features dynamic posing and authentic character likeness, perfectly capturing the essence of the original IP.

3. High-Definition Paint Application:

Expertly hand-painted with precision airbrushing and meticulous wash techniques for unparalleled depth and realism.

Features advanced painting effects such as subtle gradients, metallic finishes, and realistic battle damage for a truly immersive display.

4. Exclusive & Collectible:

Produced in a strictly limited edition (e.g., [Number] pieces worldwide), ensuring exclusivity and long-term value for collectors.

Each piece includes a unique serial number and a certificate of authenticity, guaranteeing its genuine origin.

5. Impressive Presence & Display Value:

Substantial size and significant weight command attention, making it the definitive centerpiece of any collection or display.

Often includes a themed base or diorama that enhances the narrative and visual impact of the character.

6. For the True Enthusiast:

The ultimate premium collectible for discerning fans and serious collectors, representing the highest tier of merchandise available.

A must-have grail item that showcases deep passion for the character and franchise

1.Superior Weather & Impact Resistance

Engineered to endure harsh outdoor conditions—resists cracking, UV damage, and temperature swings.

2.High Flexibility & Tear Resistance

Stretches without losing shape and withstands repeated use, ideal for rugged outdoor crafting and DIY projects.

3.Eco-Friendly & Reusable

Made from durable, non-toxic rubber—perfect for sustainable outdoor living and reducing waste.

4.Perfect for Outdoor Creations

Design custom garden decorations, pathway markers, bird feeders, and camping accessories with ease.

5.Easy Demolding & Sharp Details

Ensures clean releases and preserves fine patterns every time, even in humid or variable outdoor environments.

6.Compact & Portable

Lightweight and easy to pack—take your molding projects anywhere, from the backyard to the trails.