Chinese factory customized rubber silicone press mold for outdoor parts

| Material | EPDM, NBR, rubber, silicone, etc | Model No | SMG-OEM-0003 |

| Color | Customized | Style | Customized |

| Origin | China | Package | customized |

| Size | Customized | Logo | customized |

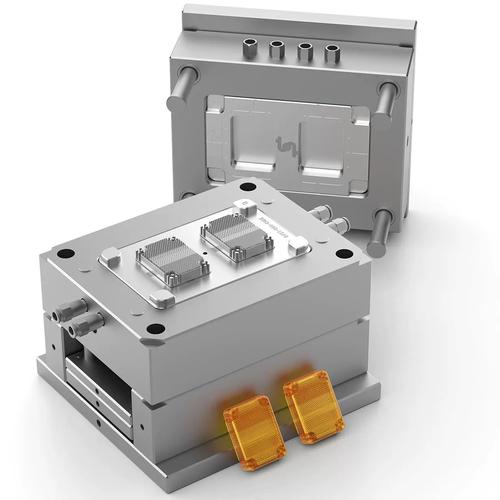

press mold.

rubber or silicone products

Part 1: Forge Unbreakable Gear: Engineer Your Outdoor Legacy with Custom Molded Components

The difference between a good outdoor product and a legendary one is found in the details—the unyielding seal that protects your critical electronics in a monsoon, the comfortable, non-slip grip that feels secure with sweaty palms on a cliff face, the silent, durable bumper that withstands years of abrasive grit and impact. At Samgo, we empower creators, engineers, and visionary outdoor brands to forge this legacy. We specialize in high-performance custom compression molded rubber and silicone parts designed explicitly for the world's harshest environments. Forget off-the-shelf components that compromise your design. Our service is your key to unlocking infinite customization—transforming your CAD drawings into functional, field-ready parts that elevate your product from a mere tool to a trusted companion on every adventure.

Whether you're prototyping a new design for a kayak hatch seal, producing a small batch of custom shock-absorbing mounts for a drone, or manufacturing a full production run of chemically resistant gaskets for overlanding equipment, our process is your end-to-end solution. We understand that outdoor gear isn't used in a controlled lab; it's subjected to UV degradation, submerged in glacial meltwater, abraded by sandstone, and exposed to fuels and repellents. That’s why our materials and molding expertise are curated to meet these extreme demands. By leveraging industry-leading compression molding technology, we create parts with superior structural integrity, exceptional material consistency, and legendary durability that injection molding or 3D printing simply cannot match. This isn't just manufacturing; it's a partnership dedicated to building outdoor gear that is built to last, perform, and define your brand's reputation for quality.

Part 2: Technical Specifications: The Anatomy of All-Weather Durability

Our custom molding process is engineered for precision, repeatability, and most importantly, resilience. We don't just make parts; we craft the building blocks of reliability for your next great product.

Material Selection Guide for Outdoor Applications:

| Material | Key Properties & Outdoor Advantages | Ideal Use Cases |

|---|---|---|

| Silicone (VMQ) | Temp Range: -60°C to 230°C (-76°F to 446°F) Excellent: UV/Ozone Resistance, Flexibility Good: Water Resistance, Electrical Insulation Fair: Abrasion Resistance | • Kayak Hatch Seals & Dry Hatches • Dive Computer & GPS Case Gaskets • High-Temp Under-Hood Components • Soft-Grip Handles for Tools • Medical/Grade Gear for First-Aid Kits |

| EPDM Rubber | Temp Range: -50°C to 150°C (-58°F to 302°F) Excellent: Weather/Ozone Resistance, Water Swell Resistance Good: Electrical Insulation, Flexibility Poor: Oil/Fuel Resistance | • Weatherproof Seals for Roof Top Tents • Cold-Weather Boot Sole Components • Gaskets for Solar Panel Mounts • Marine & Dock Hardware Buffers • Irrigation System Seals for Campers |

| Nitrile (NBR) | Temp Range: -40°C to 120°C (-40°F to 248°F) Excellent: Oil & Fuel Resistance Good: Abrasion & Tear Resistance Poor: Weather/UV Resistance | • Fuel Cap Seals for Overlanding Vehicles • Oil-Resistant Grommets & Washers • Hydraulic System Seals for Winches • Durable O-Rings for Repair Kits • Grips for Oil-Prone Tools |

| Neoprene (CR) | Temp Range: -50°C to 120°C (-58°F to 248°F) Excellent: Weather/Moderate Oil Resistance Good: Abrasion Resistance, Flexibility Fair: Flame Retardancy | • Wetsuit Seams & Components (non-skin contact) • Vibration-Dampening Mounts for Cameras • Protective Bumpers for Roof Racks & Kayaks • Laptop Sleeve Corners for Adventure Photogs • General-Purpose Protective Pads |

| Thermoplastic Elastomer (TPE) | Temp Range: -50°C to 120°C (-58°F to 248°F) Excellent: Grip Feel, Colorability Good: Flexibility, Recyclability Fair: General Weather Resistance | • Overmolded Grips on Knives, Axes, & Tools • Comfortable Straps for Headlamps & Bags • Shock-Absorbing Lens Rims for Binoculars • Non-Marring Feet for Camp Furniture • Customizable Buttons for Rugged Electronics |

The Compression Molding Advantage:

Unmatched Durability: Produces parts with superior tensile and tear strength, crucial for components like boot soles, load-bearing straps, and protective bumpers.

Material Integrity: The heat and pressure create a uniform cross-link density, eliminating weak points and ensuring consistent performance across the entire part.

Exceptional Sealing Capability: Perfect for creating reliable, long-lasting environmental seals for waterproof enclosures, dry boxes, and electrical connectors.

High-Volume Efficiency: While perfect for prototyping, the process is optimized for cost-effective medium to high-volume production runs, scaling with your success.

Part 3: Your Vision, Field-Tested and Ready for Adventure

Your journey from concept to a customer's trusted gear should be seamless, reliable, and driven by expertise. Our service is designed to be an extension of your R&D team, providing the manufacturing muscle to bring your most ambitious ideas to life.

Our End-to-End Process Simplifies Production:

Design & Quote: Submit your drawings or samples. Our engineering team will review for manufacturability and recommend the ideal material for your application, providing a transparent quote and timeline.

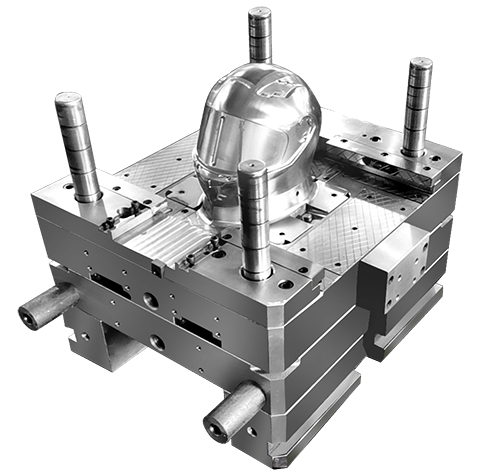

Tooling & Prototyping: We precision-machine your custom mold tools in-house. You'll receive initial samples for rigorous testing and approval, ensuring everything meets your exact specifications before full production.

Production & Quality Assurance: Once approved, we move to full-scale production. Every batch undergoes stringent quality checks for dimensions, durometer (hardness), and visual defects, guaranteeing you receive nothing short of perfect parts.

Delivery & Support: Your components are carefully packaged and shipped directly to your door, ready for assembly. We remain your partner for future iterations or new projects.

Applications That Define the Outdoors:

Imagine the possibilities. Create a completely custom, weatherproof switch boot for a new flashlight model. Develop a unique, compliant grip for a trekking pole that reduces arm fatigue. Engineer a silent, non-scuffing foot for a high-end camp chair. Produce a small batch of branded, oil-resistant valve caps for a bike repair kit. Your design is the only limit.

Why Partner With Us?

Outdoor Industry Expertise: We speak your language and understand the unique challenges of outdoor products.

Rapid Prototyping: Accelerate your time-to-market and iterate designs quickly without massive upfront costs.

Uncompromising Quality: We use only top-tier raw materials and uphold strict quality control standards.

Scalability: Grow with us from a prototype of 50 units to a production run of 50,000 without changing suppliers.

Take the First Step Toward Building Better Gear.

Contact us today for a free design review and quote. Let's discuss your project and how our custom compression molding capabilities can make your next product the most reliable one on the mountain, the trail, or the water.

What exactly are your OEM services?

Our OEM (Original Equipment Manufacturing) service allows you to bring your unique outdoor gear ideas to life. We handle the entire product development and manufacturing process based on your specifications, designs, and brand requirements. From initial concept and material sourcing to prototyping, production, and quality control, we become your dedicated manufacturing partner. Your brand logo and identity will be applied to the final products.What is your MOQ (Minimum Order Quantity)?

We understand that brands need flexibility, especially when launching new products. Therefore, we offer flexible MOQs, which vary depending on the product complexity, materials required, and customization level. We encourage you to discuss your project with us, and we will do our best to propose a feasible MOQ.Can you help us develop a product from just an idea or a sketch?

Absolutely! We specialize in turning concepts into high-quality, market-ready products. Our product development team will work closely with you to refine your idea, select appropriate materials, create technical drawings, and develop prototypes until your vision is perfectly realized.What are the typical steps in the OEM process with your company?

1.Initial Inquiry & Consultation: You share your concept, target market, and requirements. 2.Quotation & Agreement: We provide a detailed quotation, and once approved, we sign a service agreement. 3.Research & Development (R&D): Our team works on technical designs, material selection, and sample development. 4.Prototyping: We create a physical prototype for your evaluation and feedback. 5. Molds:After design confirming, we will creat mold before production. 5.Sample Approval: You approve the final sample, confirming quality, design, and functionality. 6.Mass Production: Upon your production order confirmation, we begin manufacturing your products. 7.Rigorous Quality Control (QC): We conduct inspections throughout production and a final random inspection before shipment. 8.Shipping & Delivery: We securely pack and arrange shipment to your designated destination.How long does the entire process take from concept to delivery?

The timeline varies significantly based on product complexity and order quantity. A general estimate is: Development & Sampling: 4-8 weeks. Mass Production: 4-6 weeks after sample approval. Please note that this is an estimate, and a precise timeline will be provided with your project quotation.Who owns the intellectual property (IP) and mold/tooling for the custom products?

You retain 100% ownership of your brand identity, designs, and product IP. For any custom molds or tooling created specifically for your project, ownership can be transferred to you upon agreement. We strictly adhere to confidentiality and will never use your designs for other clients.How do you determine the price for an OEM order?

The unit price is determined by several factors, including: Product complexity and design Cost of raw materials Labor and manufacturing processes involved Order quantity Packaging requirements We strive to offer competitive pricing without compromising on quality.What is your quality control process?

Quality is our top priority. Our QC process includes: Incoming Quality Control (IQC): Inspection of all raw materials. In-Process Quality Control (IPQC): Checks during key stages of production. Pre-Shipment Inspection (PSI): A final random inspection of finished products against your approved sample and our quality standards. We can provide detailed QC reports.Can we inspect the products before they are shipped?

Yes. We highly recommend a pre-shipment inspection. You are welcome to send your own QC inspector, or you can hire a third-party inspection company to perform the check at our factory. We can also provide you with photos and videos of the production and final products.How do you handle shipping?

We have extensive experience in shipping outdoor gear globally. We can handle the logistics for you and arrange shipment via sea (for large volumes) or air (for smaller, urgent orders). We work with reliable freight forwarders to ensure a smooth process. Shipping costs will be included in your final quotation.

Related Products