Customized small quantity production silicone prototype mold

| Material | ABS, PC, Nylon, Silicone, Rubber | Model No | SMG-OEM-0002-C |

| Color | Customized | Style | Customized |

| Origin | China | Package | customized |

| Size | Customized | Logo | customized |

Part 1: Revolutionize Your Outdoor Gear Design with Professional-Grade Silicone Mold Making

Welcome to the future of outdoor gear prototyping and small-batch production. For designers, engineers, and hardcore outdoor enthusiasts, the journey from a brilliant concept to a tangible, functional product is fraught with challenges. Traditional methods like 3D printing are excellent for initial form studies but often lack the durability, material properties, and fine finish required for true functional testing. Outsourcing to professional molders involves high costs, minimum order quantities, and agonizing wait times, stifling creativity and rapid iteration. Our Professional Silicone Mold Making Kit for Outdoor Gear is engineered to shatter these barriers. This isn't just a craft kit; it's a comprehensive desktop manufacturing solution designed to empower you to create high-fidelity, durable, and functional prototypes right in your workshop, garage, or studio. Whether you're perfecting the ergonomic grip of a hiking pole handle, testing the sealing capability of a custom drone housing, validating the flexibility of a buckle component, or producing a small run of bespoke gifts for your brand, this kit provides the precision, strength, and versatility demanded by the harsh realities of the outdoors.

Imagine being able to test a new carabiner design in actual weather conditions, feel the grip of a new knife handle after a day in the rain, or verify the waterproof integrity of a custom action camera mount—all before you ever commit to expensive steel tooling. Our platinum-cure silicone rubber system is formulated to capture microscopic details from your 3D printed, sculpted, or master pattern, ensuring that every ridge, texture, and undercut is perfectly reproduced. The resulting molds are incredibly tough, resistant to tearing, and can withstand the high pressures and exothermic heat of casting robust polyurethane resins that mimic final production materials like ABS, Nylon, and Polypropylene. This process, known as room temperature vulcanization (RTV) molding, is the industry's secret for rapid prototyping, and now it's accessible, affordable, and optimized for your ambitious outdoor projects. You maintain complete control over the entire product development cycle, dramatically reducing time-to-market and enabling limitless innovation.

Part 2: Unmatched Technical Specifications & Performance Data

Our kit is meticulously curated with premium materials to deliver professional results consistently. We don't cut corners, because your prototypes need to survive the real world.

Kit Contents & Technical Specifications:

| Component | Specification & Details | Purpose & Benefit |

|---|---|---|

| Platinum-Cure Silicone Rubber (1:1 Mix Ratio) | Viscosity: 4,000 cP | A low-viscosity formula that easily flows around complex geometries, trapping zero air bubbles and capturing every minute detail of your master pattern. |

| (Base & Catalyst) | Pot Life: 45 minutes | Provides ample working time to mix, degas, and pour without rushing, ensuring a stress-free process. |

| Cure Time: 4-6 hours | A rapid turnaround means you can de-mold and begin casting your first parts within the same workday. | |

| Shore Hardness: 20A | The perfect balance of flexibility for easy de-molding and rigidity to hold shape during casting, perfect for parts with deep undercuts. | |

| Tear Strength: 45 kN/m | Exceptional resistance to tearing, significantly extending the life of your mold for dozens of high-quality reproductions. | |

| Volume Options: 500g, 1000g, 5000g | Scale your project appropriately, from small components to larger gear pieces. | |

| Polyurethane Casting Resin (1:1 Mix Ratio) | Shore Hardness: 80D (Simulates ABS/Nylon) | Produces strong, rigid, and functional parts that can be drilled, tapped, sanded, and painted. Ideal for structural components. |

| Pot Life: 3 minutes | Sets extremely fast, allowing for quick production of multiple parts from a single mold in a short period. | |

| Cure Time: 30 minutes | Achieve full strength and stability rapidly, enabling immediate testing and evaluation. | |

| High-Temp Resistance Silicone (Optional Upgrade) | Resists temps up to 230°C (446°F) | Essential for casting low-melt metals like tin or Bismuth alloys for extreme durability testing or metal parts. |

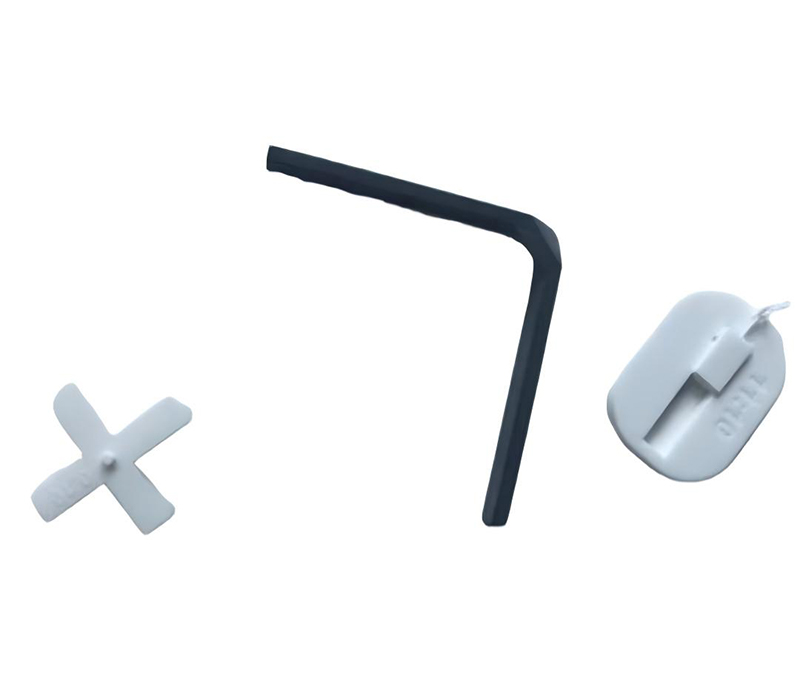

| Accessory Kit | Includes: | Everything you need for a clean, precise, and successful molding project: |

| - Measuring Cups & Sticks | For exact 1:1 volume measurements of both silicone and resin. | |

| Wooden Mixing Sticks | For thorough, consistent mixing of components. | |

| Disposable Gloves & Spatulas | To keep you safe and your workspace clean from uncured materials. | |

| Detailed Instruction Manual | A step-by-step guide with pro-tips on mold box creation, degassing, and de-molding. |

Performance Advantages for Outdoor Applications:

Weather & UV Resistance: The silicone molds themselves are inherently resistant to moisture and UV degradation, ensuring consistent performance even if your workspace is in a garage or under a canopy.

Chemical Inertness: The cured silicone is non-reactive, allowing you to use a wide variety of casting resins, including those with additives for color, flexibility, or strength, without fear of the mold degrading.

Exceptional Dimensional Stability: The low shrinkage rate (<0.1%) of our silicone during curing guarantees that your cast parts are dimensionally identical to your original master, which is critical for parts that need to fit together with precision, such as housing shells or interlocking components.

Long Mold Life: A single well-made mold can produce 20-50+ copies depending on the part's complexity, making it perfectly suited for small-batch production, limited edition runs, or creating a full set of components for thorough field testing.

Part 3: Your End-to-End Solution for Agile Product Development

The true power of this kit lies in its application throughout your entire product development lifecycle. It transforms a linear, costly process into an agile, iterative, and deeply creative one.

Phase 1: Design Validation & Functional Testing. This is where the kit truly shines. Instead of relying on fragile 3D prints, you can cast parts in resins that closely mimic the intended final material. Test the impact resistance of a new buckle design by throwing it against rock, check the grip of a handle when it's wet and muddy, or verify the aerodynamic properties of a component. You can iterate the design, print a new master, and create a new mold in less than 24 hours. This rapid feedback loop saves thousands of dollars in potential tooling modifications down the line and ensures your product is truly field-ready.

Phase 2: User Feedback & Market Testing. Before investing in mass production, create a small batch of 10-20 high-quality, functional prototypes. Use them yourself on extended expeditions, or give them to a trusted group of beta testers. Feedback on real, durable products is infinitely more valuable than feedback on a non-functional model. This validates your market and creates early buzz for your upcoming product launch. You can also use these casts for stunning product photography and videography long before your mass-produced units arrive.

Phase 3: Small-Batch Production & Customization. For many creators, the goal isn't mass production. It's about producing unique, high-value, custom-made gear. This kit is your manufacturing plant. Produce limited edition, colored components for premium clients. Create custom-branded gear for events or partnerships. Manufacture replacement parts for older, discontinued gear. The possibilities are limited only by your imagination. You have complete control over output, timing, and cost.

Your Success is Our Goal. We are committed to supporting makers in the outdoor community. Our detailed guide walks you through your first mold, and our customer support team is comprised of individuals who use this kit for their own projects. We understand the nuances of molding a complex gear part and are here to help you succeed.

Order now and take the first step towards unparalleled design freedom. Build, test, and iterate like a professional—direct from your bench.

What exactly are your OEM services?

Our OEM (Original Equipment Manufacturing) service allows you to bring your unique outdoor gear ideas to life. We handle the entire product development and manufacturing process based on your specifications, designs, and brand requirements. From initial concept and material sourcing to prototyping, production, and quality control, we become your dedicated manufacturing partner. Your brand logo and identity will be applied to the final products.What is your MOQ (Minimum Order Quantity)?

We understand that brands need flexibility, especially when launching new products. Therefore, we offer flexible MOQs, which vary depending on the product complexity, materials required, and customization level. We encourage you to discuss your project with us, and we will do our best to propose a feasible MOQ.Can you help us develop a product from just an idea or a sketch?

Absolutely! We specialize in turning concepts into high-quality, market-ready products. Our product development team will work closely with you to refine your idea, select appropriate materials, create technical drawings, and develop prototypes until your vision is perfectly realized.What are the typical steps in the OEM process with your company?

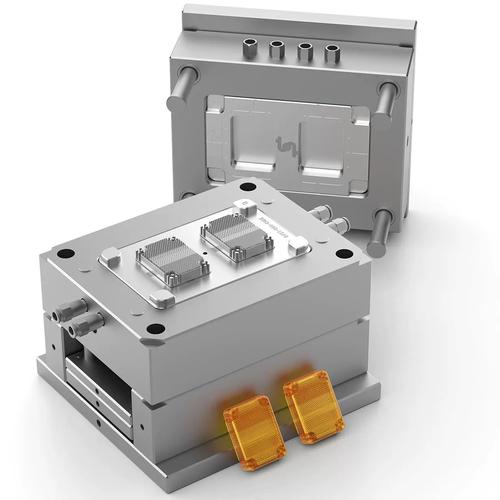

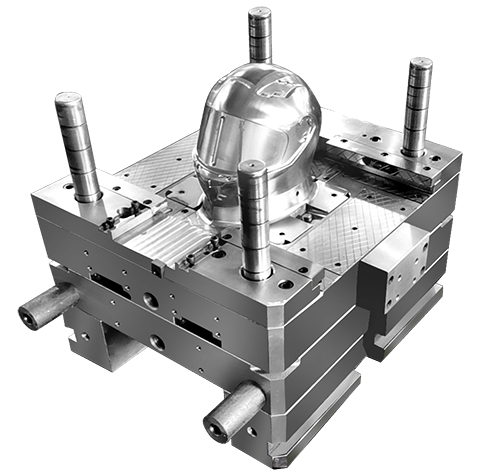

1.Initial Inquiry & Consultation: You share your concept, target market, and requirements. 2.Quotation & Agreement: We provide a detailed quotation, and once approved, we sign a service agreement. 3.Research & Development (R&D): Our team works on technical designs, material selection, and sample development. 4.Prototyping: We create a physical prototype for your evaluation and feedback. 5. Molds:After design confirming, we will creat mold before production. 5.Sample Approval: You approve the final sample, confirming quality, design, and functionality. 6.Mass Production: Upon your production order confirmation, we begin manufacturing your products. 7.Rigorous Quality Control (QC): We conduct inspections throughout production and a final random inspection before shipment. 8.Shipping & Delivery: We securely pack and arrange shipment to your designated destination.How long does the entire process take from concept to delivery?

The timeline varies significantly based on product complexity and order quantity. A general estimate is: Development & Sampling: 4-8 weeks. Mass Production: 4-6 weeks after sample approval. Please note that this is an estimate, and a precise timeline will be provided with your project quotation.Who owns the intellectual property (IP) and mold/tooling for the custom products?

You retain 100% ownership of your brand identity, designs, and product IP. For any custom molds or tooling created specifically for your project, ownership can be transferred to you upon agreement. We strictly adhere to confidentiality and will never use your designs for other clients.How do you determine the price for an OEM order?

The unit price is determined by several factors, including: Product complexity and design Cost of raw materials Labor and manufacturing processes involved Order quantity Packaging requirements We strive to offer competitive pricing without compromising on quality.What is your quality control process?

Quality is our top priority. Our QC process includes: Incoming Quality Control (IQC): Inspection of all raw materials. In-Process Quality Control (IPQC): Checks during key stages of production. Pre-Shipment Inspection (PSI): A final random inspection of finished products against your approved sample and our quality standards. We can provide detailed QC reports.Can we inspect the products before they are shipped?

Yes. We highly recommend a pre-shipment inspection. You are welcome to send your own QC inspector, or you can hire a third-party inspection company to perform the check at our factory. We can also provide you with photos and videos of the production and final products.How do you handle shipping?

We have extensive experience in shipping outdoor gear globally. We can handle the logistics for you and arrange shipment via sea (for large volumes) or air (for smaller, urgent orders). We work with reliable freight forwarders to ensure a smooth process. Shipping costs will be included in your final quotation.

Related Products