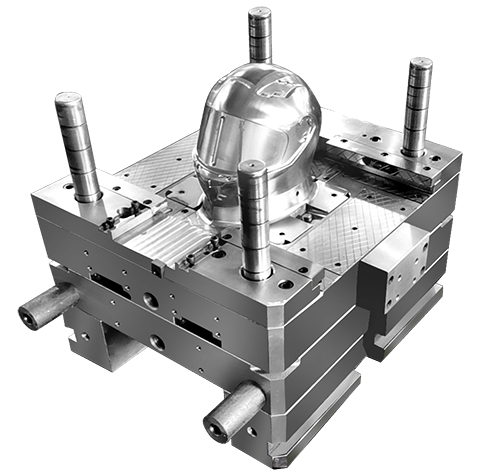

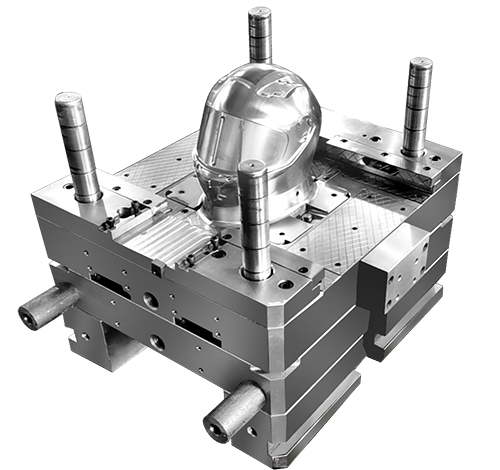

Precision Injection Molds for Safety Helmets

Precision Injection Molds for Safety Helmets: Where Protection Meets Performance

Introduction

In the realm of personal protective equipment (PPE), a helmet is a critical lifeline. Its integrity begins not on the production line, but within the precision of its mold. Our advanced injection molds for plastic helmets are engineered to be the cornerstone of your manufacturing process, delivering unmatched consistency, superior impact strength, and operational efficiency. We partner with you to create the foundation for safety you can trust.

1. Core Engineering Advantages

Our molds are built on a foundation of innovative engineering, designed to maximize performance, durability, and return on investment.

Core Advantages Comparison Table

| Advantage | Conventional Mold | Our Advanced Helmet Mold | Your Benefit |

|---|---|---|---|

| Structural Integrity | Basic flow leading to potential weak points. | CAE-Optimized Melt Flow & Gating | Superior, consistent impact resistance across the entire helmet shell, crucial for safety certification. |

| Production Uptime | Standard materials leading to wear and maintenance. | High-Grade Stainless Steel (420SS/NAK80) on critical surfaces. | Extended mold life, reduced polishing frequency, and consistent part quality over millions of cycles. |

| Cycle Time & Efficiency | Straight-drilled cooling channels. | Conformal Cooling Channels following the helmet's complex geometry. | Up to 30% faster cycle times, reduced energy consumption, and elimination of warpage. |

| Automation Readiness | Manual part handling. | Integrated Robotic Interface & Automatic Undercore | Fully automated, lights-out production, reduced labor costs, and elimination of handling damage. |

2. In-Depth Technical Specifications

Every component is specified to meet the rigorous demands of high-volume, high-quality safety helmet production.

Technical Specifications Table

| Category | Specification | Impact on Final Product |

|---|---|---|

| Mold Base & Plates | Standard 1050/1715 Steel; Precision ground and hardened. | Provides absolute rigidity and stability, preventing deflection under high injection pressure. |

| Cavity & Core | Premium Stainless Steel (420SS); High-Polish (SPI A1) or textured finish. | Guarantees a flawless Class-A surface finish, free of flow lines or blemishes, right from the press. |

| Gating System | Hot Runner System with valve-gate sequencing. | Elimates material waste (no runner), ensures balanced filling, and allows for a clean gate separation. |

| Ejection System | Ejector Sleeves & Blades with guided ejector plates and proximity sensors. | Ensures gentle, yet positive, ejection from the complex undercuts without stressing or marking the helmet. |

| Cooling System | 3D Conformal Cooling with baffles and bubblers in deep core areas. | Enables uniform heat extraction, critical for achieving consistent molecular orientation and impact strength. |

| Venting | Precision micro-vents at parting lines and ejector pins. | Prevents gas traps (burn marks) and vacuum issues, ensuring a defect-free shell and stable demolding. |

3. Product Features & Tangible Benefits

Our design philosophy translates technical features into direct benefits for your production and product quality.

Feature: CAE-Optimized Filling & Packing

Benefit: Using advanced Computer-Aided Engineering (CAE), we simulate the flow of plastic to ensure perfect filling balance and optimal packing pressure. This process is critical for eliminating weak spots and internal stresses, resulting in a helmet shell with homogeneous impact strength that reliably passes stringent safety tests like ANSI/ISEA Z89.1 or EN 397.

Feature: Automated Undercore & Robotic Extraction

Benefit: The helmet's inner geometry creates significant undercuts. Our mold incorporates an automated undercore mechanism that retracts before ejection, allowing for a damage-free demolding process. Coupled with standardized interfaces for robotic arms, this enables a fully automated production cell, maximizing output and ensuring gentle handling of the finished product.

Feature: Superior Surface Finish Options

Benefit: The cavity is machined and finished to the highest standards, capable of achieving a high-gloss polish (SPI A1) for a premium look or a variety of textures (grain, matte). This ensures your helmets have an exceptional aesthetic appeal straight from the mold, reducing the need for secondary operations and enhancing brand perception.

4. Our Service & Partnership Commitment

We are more than a supplier; we are your technical partner in manufacturing excellence.

Comprehensive DFM (Design for Manufacturability) Report: Before any steel is cut, we provide a detailed analysis of your helmet design, suggesting optimizations for moldability, cost, and performance to de-risk your project.

Prototyping & Validation Support: We support the creation of initial samples for safety testing and marketing, ensuring the final product meets all requirements before mass production.

Global Technical Support & Maintenance: Our commitment doesn't end at delivery. We offer lifelong technical support, spare parts, and maintenance services to ensure your mold operates at peak performance for its entire lifecycle.

Conclusion: The Foundation of Safety Starts Here

The integrity of every helmet you produce is fundamentally linked to the quality of its mold. By investing in our precision-engineered injection mold solution, you are not just purchasing a tool; you are securing a reliable, efficient, and high-quality foundation for your most critical PPE products.

Contact us today to schedule a consultation and receive a free, no-obligation DFM analysis of your helmet design. Let's build a safer world, together.

What exactly are your OEM services?

Our OEM (Original Equipment Manufacturing) service allows you to bring your unique outdoor gear ideas to life. We handle the entire product development and manufacturing process based on your specifications, designs, and brand requirements. From initial concept and material sourcing to prototyping, production, and quality control, we become your dedicated manufacturing partner. Your brand logo and identity will be applied to the final products.What is your MOQ (Minimum Order Quantity)?

We understand that brands need flexibility, especially when launching new products. Therefore, we offer flexible MOQs, which vary depending on the product complexity, materials required, and customization level. We encourage you to discuss your project with us, and we will do our best to propose a feasible MOQ.Can you help us develop a product from just an idea or a sketch?

Absolutely! We specialize in turning concepts into high-quality, market-ready products. Our product development team will work closely with you to refine your idea, select appropriate materials, create technical drawings, and develop prototypes until your vision is perfectly realized.What are the typical steps in the OEM process with your company?

1.Initial Inquiry & Consultation: You share your concept, target market, and requirements. 2.Quotation & Agreement: We provide a detailed quotation, and once approved, we sign a service agreement. 3.Research & Development (R&D): Our team works on technical designs, material selection, and sample development. 4.Prototyping: We create a physical prototype for your evaluation and feedback. 5. Molds:After design confirming, we will creat mold before production. 5.Sample Approval: You approve the final sample, confirming quality, design, and functionality. 6.Mass Production: Upon your production order confirmation, we begin manufacturing your products. 7.Rigorous Quality Control (QC): We conduct inspections throughout production and a final random inspection before shipment. 8.Shipping & Delivery: We securely pack and arrange shipment to your designated destination.How long does the entire process take from concept to delivery?

The timeline varies significantly based on product complexity and order quantity. A general estimate is: Development & Sampling: 4-8 weeks. Mass Production: 4-6 weeks after sample approval. Please note that this is an estimate, and a precise timeline will be provided with your project quotation.Who owns the intellectual property (IP) and mold/tooling for the custom products?

You retain 100% ownership of your brand identity, designs, and product IP. For any custom molds or tooling created specifically for your project, ownership can be transferred to you upon agreement. We strictly adhere to confidentiality and will never use your designs for other clients.How do you determine the price for an OEM order?

The unit price is determined by several factors, including: Product complexity and design Cost of raw materials Labor and manufacturing processes involved Order quantity Packaging requirements We strive to offer competitive pricing without compromising on quality.What is your quality control process?

Quality is our top priority. Our QC process includes: Incoming Quality Control (IQC): Inspection of all raw materials. In-Process Quality Control (IPQC): Checks during key stages of production. Pre-Shipment Inspection (PSI): A final random inspection of finished products against your approved sample and our quality standards. We can provide detailed QC reports.Can we inspect the products before they are shipped?

Yes. We highly recommend a pre-shipment inspection. You are welcome to send your own QC inspector, or you can hire a third-party inspection company to perform the check at our factory. We can also provide you with photos and videos of the production and final products.How do you handle shipping?

We have extensive experience in shipping outdoor gear globally. We can handle the logistics for you and arrange shipment via sea (for large volumes) or air (for smaller, urgent orders). We work with reliable freight forwarders to ensure a smooth process. Shipping costs will be included in your final quotation.

Related Products