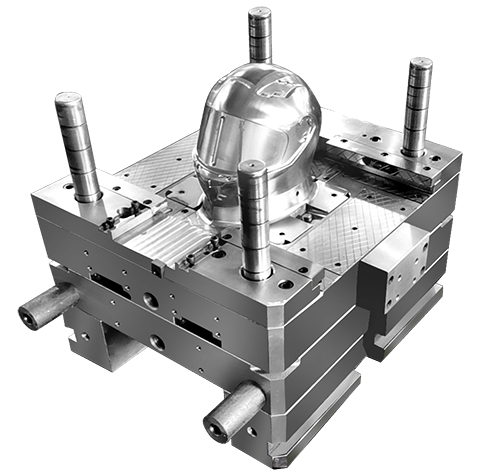

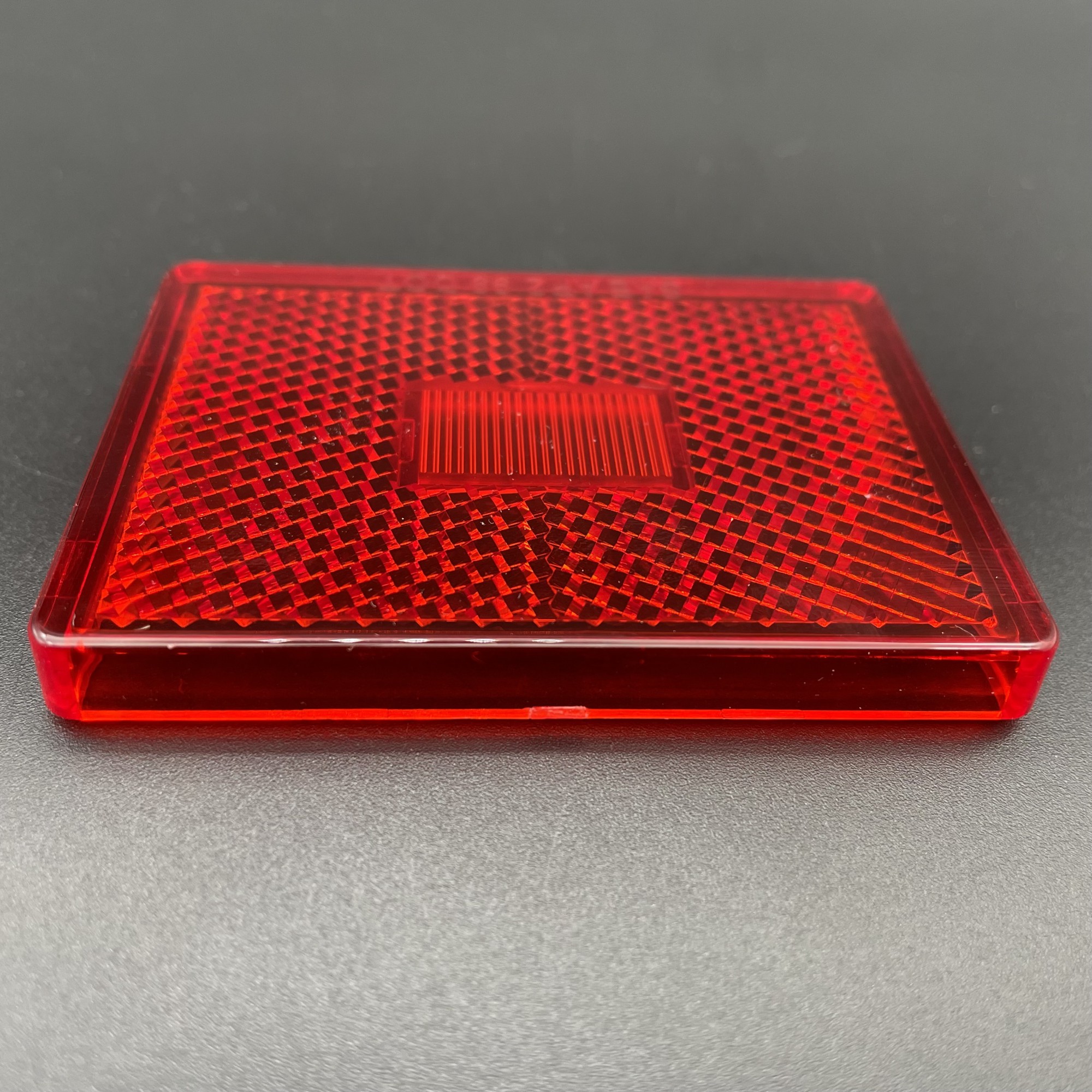

OEM customized lampshade injection mold

Precision Injection Mold for Lampshades: Engineered for Brilliance & Efficiency

Welcome to the future of lampshade manufacturing. Our Precision Lampshade Injection Mold is not just a tool; it is a comprehensive solution designed to maximize your production output, ensure flawless product quality, and minimize operational costs. Engineered with cutting-edge technology and robust materials, this mold sets a new benchmark for efficiency and reliability in the lighting industry.

Unmatched Product Advantages

Our mold is built to deliver tangible benefits that directly impact your bottom line.

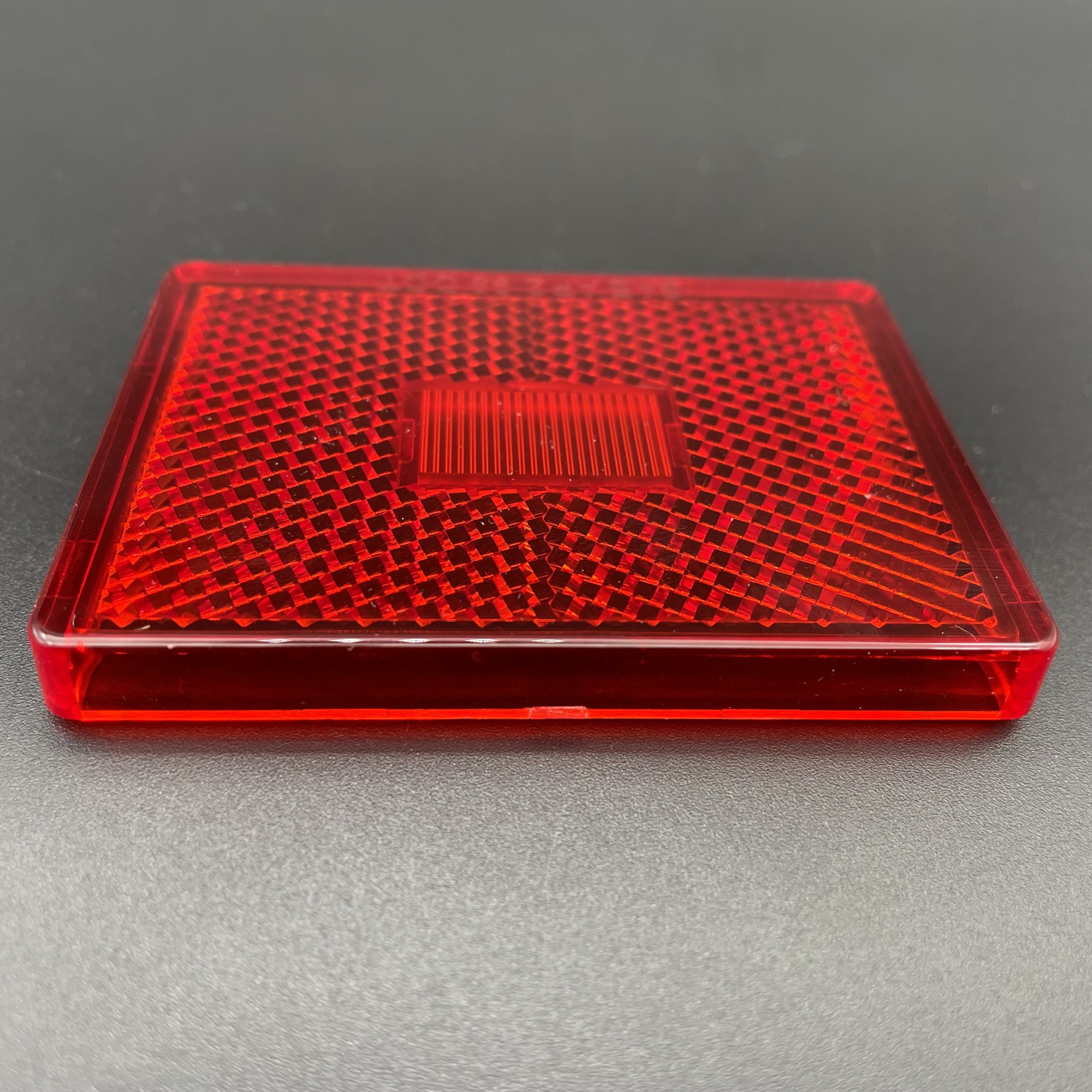

Flawless Aesthetic Quality: The mold cavities are meticulously polished and often textured or chrome-plated to produce lampshades with an exceptional, high-gloss finish right out of the press. This eliminates the need for secondary finishing processes, saving both time and money.

High-Speed Production Capability: With an optimized cooling channel design and efficient ejection system, our molds achieve remarkably short cycle times. This means you can produce more units per hour, meeting high market demand with ease.

Exceptional Durability & Longevity: Constructed from premium-grade hardened steels (e.g., H13, S136), the mold core and cavity are built to withstand the abrasion of filled materials and the rigors of long-term, high-volume production runs, ensuring a consistently high return on investment.

Optimized for Material Efficiency: The integrated hot runner system (optional) and precision gating ensure minimal material waste. You use only the plastic required, reducing raw material costs and making your process more sustainable.

Easy Maintenance & Operational Simplicity: Designed for quick mold changes and easy access to wear parts, our molds reduce downtime significantly. Simplified maintenance protocols mean your team can perform upkeep faster and more effectively.

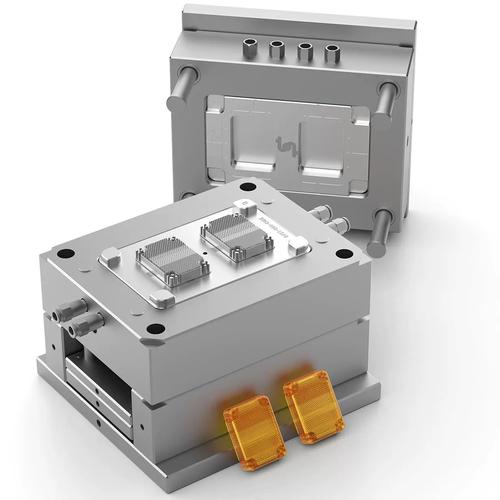

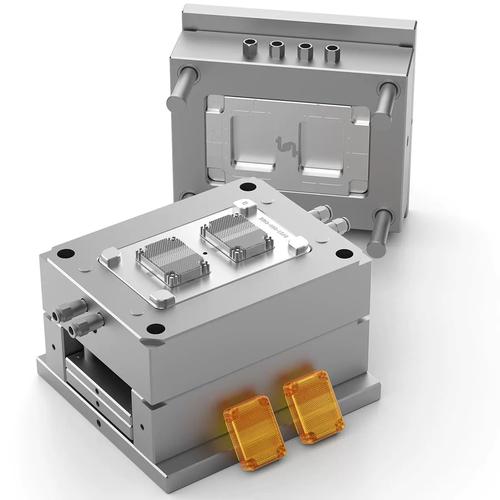

Technical Specifications & Design Features

The following table outlines the core technical specifications and advanced design features that make this mold a superior choice.

| Category | Specification | Benefit |

|---|---|---|

| Mold Base Material | Premium 1.2311 / P20 Steel | Provides excellent toughness and stability for long production life. |

| Cavity & Core Material | Hardened H13 or Stainless S136 Steel | Superior wear and corrosion resistance, ideal for high-gloss finishes and engineering plastics. |

| Cooling System | Conformal Cooling Channels (Highly Recommended) | Follows the contour of the lampshade for uniform and rapid heat extraction, reducing cycle times by up to 30% and minimizing warpage. |

| Runner System | Hot Runner System (Standard) | Eliminates sprue and runner waste, ensures consistent melt temperature, and allows for fully automated production. |

| Ejection System | Customized Ejector Pins + Sleek Sleeves | Ensures smooth, reliable, and mark-free ejection of the delicate lampshade, preventing damage and cosmetic defects. |

| Venting | Strategic Micro-Vents | Prevents gas traps and burn marks, ensuring a perfect surface finish on the final product. |

| Compatibility | Universal Mounting Standard (e.g., HASCO, DME) | Ensures easy integration into a wide range of injection molding machines. |

Ideal for a Wide Range of Applications

Our versatile mold design can be adapted to produce lampshades for various sectors and styles:

Residential Lighting: Beautiful and consistent shades for table lamps, floor lamps, pendants, and ceiling fixtures.

Commercial & Hospitality Lighting: Durable and high-quality shades for hotels, restaurants, offices, and retail spaces.

Decorative & Architectural Lighting: Custom-designed shades with complex geometries and precise optical requirements.

Material Versatility: Successfully tested with a range of thermoplastics including PMMA (Acrylic) for crystal clarity, PC (Polycarbonate) for impact resistance, PS (Polystyrene) for cost-effectiveness, and ABS for a good balance of strength and finish.

Our Service and Support Commitment

Investing in our mold means investing in a partnership. We provide comprehensive support from concept to production.

DFM (Design for Manufacturability) Analysis: Our engineering team works with you from the start to optimize your lampshade design for the injection molding process, identifying potential issues before manufacturing begins.

Prototyping Service: We can produce initial samples for your evaluation, ensuring the final product meets all your specifications.

Lifetime Technical Support: Our relationship doesn't end at delivery. We offer ongoing technical support and maintenance advice to ensure your mold operates at peak performance throughout its entire lifecycle.

Conclusion: A Smart Investment for Your Business

In the competitive lighting market, efficiency, quality, and reliability are paramount. Our Precision Lampshade Injection Mold is engineered to deliver on all three. By reducing cycle times, eliminating defects, and extending tool life, this mold is not an expense—it's a strategic investment that will drive your profitability for years to come.

Contact us today to discuss your specific lampshade project and receive a customized quotation. Let us help you shine brighter.

What exactly are your OEM services?

Our OEM (Original Equipment Manufacturing) service allows you to bring your unique outdoor gear ideas to life. We handle the entire product development and manufacturing process based on your specifications, designs, and brand requirements. From initial concept and material sourcing to prototyping, production, and quality control, we become your dedicated manufacturing partner. Your brand logo and identity will be applied to the final products.What is your MOQ (Minimum Order Quantity)?

We understand that brands need flexibility, especially when launching new products. Therefore, we offer flexible MOQs, which vary depending on the product complexity, materials required, and customization level. We encourage you to discuss your project with us, and we will do our best to propose a feasible MOQ.Can you help us develop a product from just an idea or a sketch?

Absolutely! We specialize in turning concepts into high-quality, market-ready products. Our product development team will work closely with you to refine your idea, select appropriate materials, create technical drawings, and develop prototypes until your vision is perfectly realized.What are the typical steps in the OEM process with your company?

1.Initial Inquiry & Consultation: You share your concept, target market, and requirements. 2.Quotation & Agreement: We provide a detailed quotation, and once approved, we sign a service agreement. 3.Research & Development (R&D): Our team works on technical designs, material selection, and sample development. 4.Prototyping: We create a physical prototype for your evaluation and feedback. 5. Molds:After design confirming, we will creat mold before production. 5.Sample Approval: You approve the final sample, confirming quality, design, and functionality. 6.Mass Production: Upon your production order confirmation, we begin manufacturing your products. 7.Rigorous Quality Control (QC): We conduct inspections throughout production and a final random inspection before shipment. 8.Shipping & Delivery: We securely pack and arrange shipment to your designated destination.How long does the entire process take from concept to delivery?

The timeline varies significantly based on product complexity and order quantity. A general estimate is: Development & Sampling: 4-8 weeks. Mass Production: 4-6 weeks after sample approval. Please note that this is an estimate, and a precise timeline will be provided with your project quotation.Who owns the intellectual property (IP) and mold/tooling for the custom products?

You retain 100% ownership of your brand identity, designs, and product IP. For any custom molds or tooling created specifically for your project, ownership can be transferred to you upon agreement. We strictly adhere to confidentiality and will never use your designs for other clients.How do you determine the price for an OEM order?

The unit price is determined by several factors, including: Product complexity and design Cost of raw materials Labor and manufacturing processes involved Order quantity Packaging requirements We strive to offer competitive pricing without compromising on quality.What is your quality control process?

Quality is our top priority. Our QC process includes: Incoming Quality Control (IQC): Inspection of all raw materials. In-Process Quality Control (IPQC): Checks during key stages of production. Pre-Shipment Inspection (PSI): A final random inspection of finished products against your approved sample and our quality standards. We can provide detailed QC reports.Can we inspect the products before they are shipped?

Yes. We highly recommend a pre-shipment inspection. You are welcome to send your own QC inspector, or you can hire a third-party inspection company to perform the check at our factory. We can also provide you with photos and videos of the production and final products.How do you handle shipping?

We have extensive experience in shipping outdoor gear globally. We can handle the logistics for you and arrange shipment via sea (for large volumes) or air (for smaller, urgent orders). We work with reliable freight forwarders to ensure a smooth process. Shipping costs will be included in your final quotation.

Related Products