News

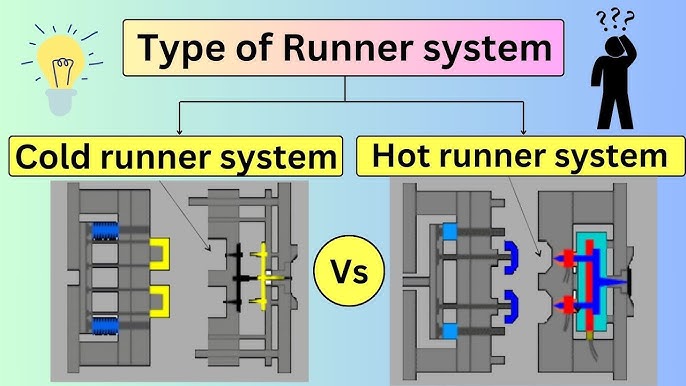

202512-01Cold Runner Systems: The traditional approach. How it works: Unheated channels solidify with each cycle, creating a runner that must be separated and recycled. Pros: Lower mold cost, better for heat-sensitive materials, easier color changes. Cons: High material waste, slower cycle times, added cost for recycling runners. Hot Runner Systems: The advanced, modern approach. How it works: A heated manifold keeps plastic molten in the channels, injecting it directly into cavities with no solid runner. Pros: Eliminates material waste, faster cycle times, superior part quality and aesthetics. Cons: Higher initial mold cost, more complex process control, difficult color changes.

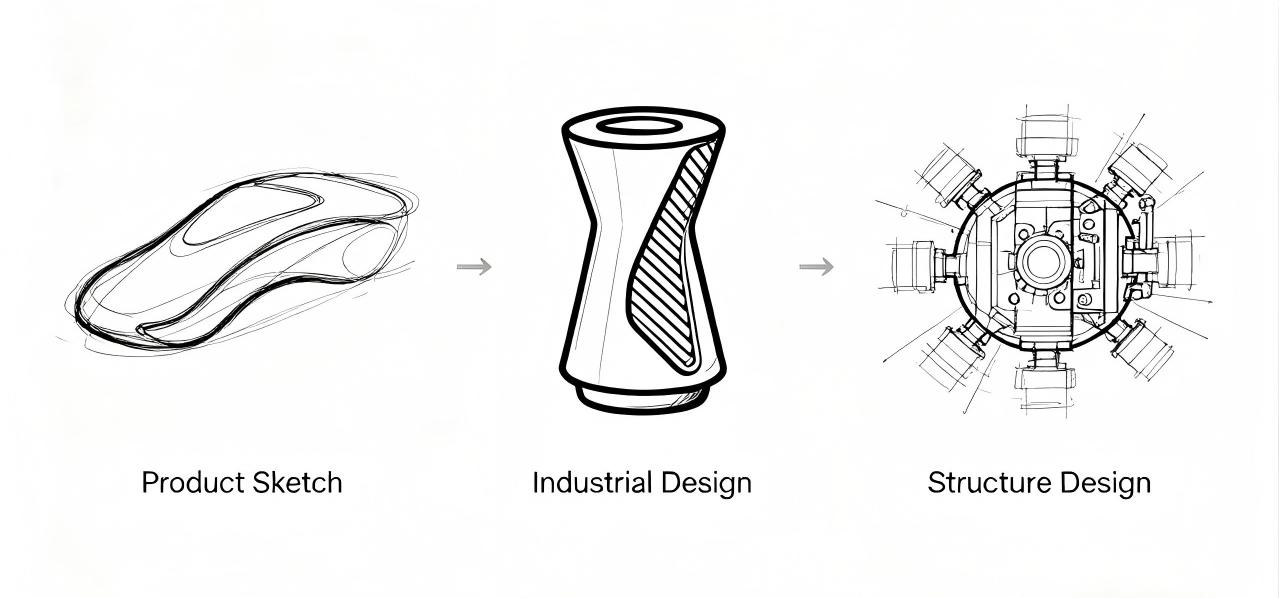

202512-01Cold Runner Systems: The traditional approach. How it works: Unheated channels solidify with each cycle, creating a runner that must be separated and recycled. Pros: Lower mold cost, better for heat-sensitive materials, easier color changes. Cons: High material waste, slower cycle times, added cost for recycling runners. Hot Runner Systems: The advanced, modern approach. How it works: A heated manifold keeps plastic molten in the channels, injecting it directly into cavities with no solid runner. Pros: Eliminates material waste, faster cycle times, superior part quality and aesthetics. Cons: Higher initial mold cost, more complex process control, difficult color changes. 202511-28Samgo provides a comprehensive OEM solution for plastic parts, seamlessly guiding your product from initial concept to high-volume mass production. Our integrated process begins with collaborative design and engineering, where we optimize your product for manufacturability (DFM) to ensure cost-effectiveness and quality. We then transition to precision mold making, crafting the durable tools required for consistent output. Finally, we leverage our state-of-the-art, automated production floor for efficient and reliable manufacturing. This end-to-end approach, supported by rigorous quality control at every stage, guarantees a streamlined workflow, faster time-to-market, and a superior final product. Partner with Samgo to simplify your supply chain and turn your innovative designs into tangible reality with a single, trusted expert.

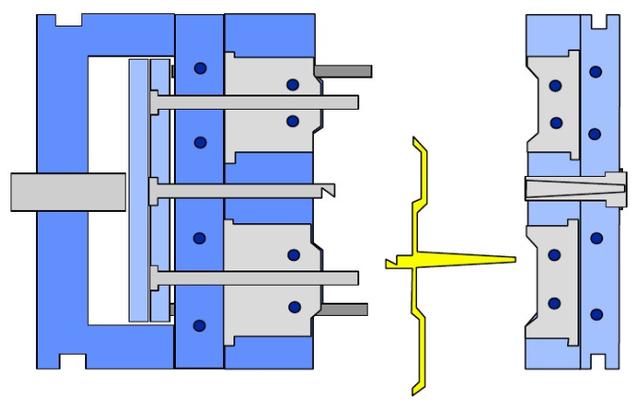

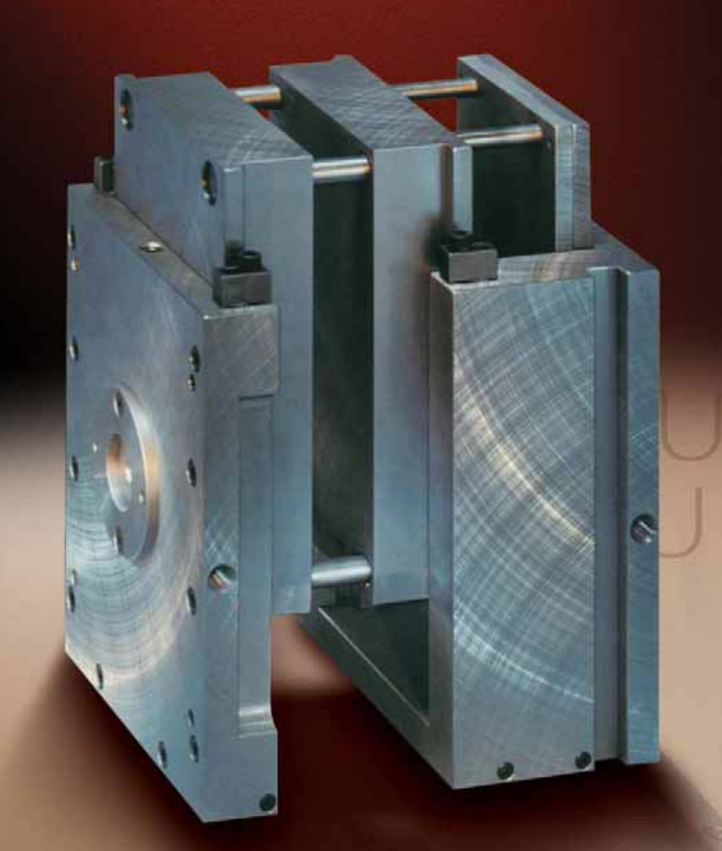

202511-28Samgo provides a comprehensive OEM solution for plastic parts, seamlessly guiding your product from initial concept to high-volume mass production. Our integrated process begins with collaborative design and engineering, where we optimize your product for manufacturability (DFM) to ensure cost-effectiveness and quality. We then transition to precision mold making, crafting the durable tools required for consistent output. Finally, we leverage our state-of-the-art, automated production floor for efficient and reliable manufacturing. This end-to-end approach, supported by rigorous quality control at every stage, guarantees a streamlined workflow, faster time-to-market, and a superior final product. Partner with Samgo to simplify your supply chain and turn your innovative designs into tangible reality with a single, trusted expert. 202511-28Samgo clarifies the key choice in injection molding. Two-plate molds offer a simpler, more cost-effective design, while three-plate molds allow for automated runner separation and central gating, ideal for high-volume automation but at a higher initial cost and complexity.

202511-28Samgo clarifies the key choice in injection molding. Two-plate molds offer a simpler, more cost-effective design, while three-plate molds allow for automated runner separation and central gating, ideal for high-volume automation but at a higher initial cost and complexity. 202510-14The call of the wild is often answered with the latest in outdoor equipment: a lightweight tent, a supportive backpack, rugged boots. But what truly defines the performance, durability, and comfort of this gear isn't its brand or color—it's the advanced materials from which it's crafted. Behind every waterproof zip, every flexible strap, and every corrosion-resistant buckle lies a story of chemical engineering and metallurgical innovation. This is a deep dive into the unsung heroes of the outdoors: the plastics, metals, and elastomers that make modern exploration possible.

202510-14The call of the wild is often answered with the latest in outdoor equipment: a lightweight tent, a supportive backpack, rugged boots. But what truly defines the performance, durability, and comfort of this gear isn't its brand or color—it's the advanced materials from which it's crafted. Behind every waterproof zip, every flexible strap, and every corrosion-resistant buckle lies a story of chemical engineering and metallurgical innovation. This is a deep dive into the unsung heroes of the outdoors: the plastics, metals, and elastomers that make modern exploration possible. 202509-25Samgo OEM service process: Product design-sample/prototype-molds-mass production

202509-25Samgo OEM service process: Product design-sample/prototype-molds-mass production