Hot Runner vs Cold Runner: The Molding Conundrum Shaping Modern Manufacturing

FOR IMMEDIATE RELEASE

In the high-stakes, high-precision world of injection molding, a critical decision lies at the heart of every project: the choice of a runner system. This seemingly simple component—the channel that delivers molten plastic from the machine nozzle to the mold cavities—can dramatically impact a part's cost, quality, and production efficiency. The industry's enduring debate centers on two primary technologies: the traditional Cold Runner and the advanced Hot Runner system.

Understanding the distinction between these systems is no longer just an engineer's concern; it is a crucial strategic consideration for anyone involved in product design, manufacturing management, and supply chain logistics.

The Established Workhorse: Cold Runner Systems

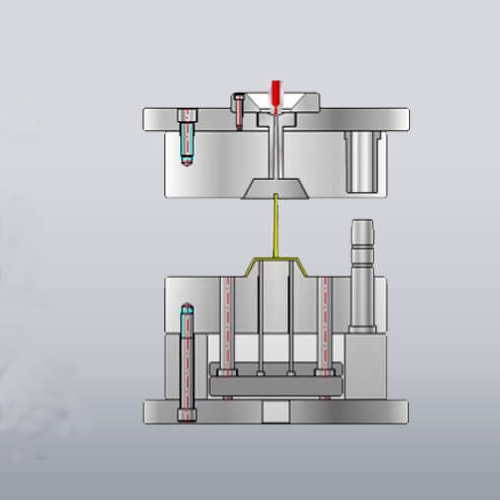

A cold runner system is the more traditional approach. It consists of channels machined into the mold plates that direct the plastic to the part cavities. As the name implies, these channels are "cold"; they are not actively heated. With each injection cycle, the plastic in these channels cools and solidifies alongside the final parts.

This solidified plastic, known as the runner, must then be separated from the finished products and is typically reground and recycled back into the process.

Advantages of Cold Runner Systems:

Lower Mold Cost: The mold design is simpler, without the need for complex heated components, leading to a lower initial investment.

Material Flexibility: Excellent for processing materials that are sensitive to heat history or degrade easily, as the material in the runner is purged with each cycle.

Easier Color Changes: Switching colors or materials is relatively straightforward, as the entire old material system (runner and parts) is ejected.

Disadvantages:

Significant Material Waste: The runner system is waste, which can account for a substantial portion of the total shot weight, especially in multi-cavity molds.

Higher Cycle Times: The thicker runner system takes longer to cool than the parts themselves, often dictating the cycle time.

Increased Labor and Energy: The regrinding and reprocessing of runners add extra steps and energy consumption to the operation.

The Modern Innovator: Hot Runner Systems

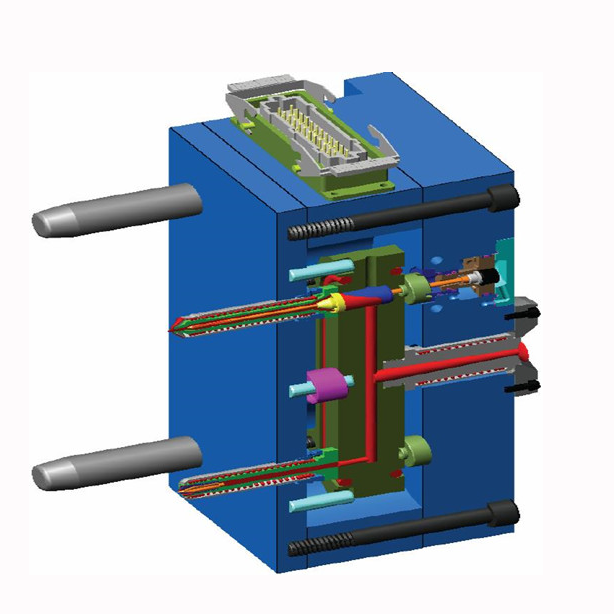

Hot runner systems represent a technological leap. In this setup, a heated manifold maintains the plastic in a molten state throughout the runner system. The material remains liquid from the machine nozzle until it is injected directly into the cavities through heated nozzles. No runner is ejected with the parts.

Advantages of Hot Runner Systems:

Elimination of Material Waste: By keeping the runner molten, the system drastically reduces or completely eliminates sprue and runner waste, leading to direct material savings.

Faster Cycle Times: Since there is no cold runner to solidify, cycle times are often determined solely by the cooling of the part itself, enabling faster production.

Improved Part Quality and Aesthetics: Hot runners provide more consistent pressure and flow, reducing part stresses and visible gate blemishes. They also allow for more flexible gate positioning.

Disadvantages:

Higher Initial Cost: The system is complex, incorporating heaters, thermocouples, and sophisticated controllers, making the mold significantly more expensive.

Complex Process Control: Requires careful temperature control and is more susceptible to issues like heating element failure or material degradation (drool) if not managed properly.

Difficult Color and Material Changes: Purging the system for a color change is more time-consuming and wasteful.

Head-to-Head: A Comparative Analysis

The following table provides a clear, side-by-side comparison of the key characteristics of both systems:

| Feature | Cold Runner System | Hot Runner System |

|---|---|---|

| Initial Mold Cost | Low to Moderate | High |

| Material Waste | High | Very Low to Zero |

| Cycle Time | Slower (runner dictates cycle) | Faster (part dictates cycle) |

| Part Quality | Good, potential for higher stress | Excellent, more consistent |

| Gate Vestige | More noticeable | Less noticeable, better aesthetics |

| Color/Material Change | Relatively Easy | Difficult and Time-Consuming |

| Maintenance | Simpler, mechanical | Complex, electrical and mechanical |

| Best For | Short runs, prototype work, heat-sensitive materials | High-volume production, expensive materials, quality-critical parts |

The Future is a Hybrid Approach

The choice between hot and cold is not always binary. "We are increasingly seeing a trend towards hybrid molds, which combine both hot and cold runner principles," says Dr. Emily Thorne, a manufacturing engineer at Plastics Innovation Inc. "A mold might use a hot runner to feed several cold runner sub-systems. This offers a balance, providing the material savings of a hot runner with the flexibility and lower cost of a cold runner for specific applications."

Conclusion: A Strategic Decision

There is no universal "best" solution. The optimal choice hinges on a detailed analysis of production volume, part design, material selection, and total lifecycle cost.

For manufacturers prioritizing low-volume production, frequent material changes, or a constrained budget, the cold runner system remains a reliable and cost-effective choice. Conversely, for high-volume manufacturing where material savings, cycle time, and superior part quality are paramount, the higher initial investment in a hot runner system delivers a compelling and rapid return on investment.

As manufacturing continues its march towards greater efficiency and sustainability, the intelligent application of these molding technologies will be a key differentiator in a competitive global market.