Shanghai, China – In the fast-paced world of original equipment manufacturing (OEM), the ability to bring a product from a mere concept to store shelves efficiently and cost-effectively is the ultimate competitive edge. Samgo, a leading provider of plastic injection molding solutions, is redefining this journey by offering a fully integrated, one-stop service that seamlessly guides clients through every stage, from initial product design to high-volume mass production.

For brands and innovators worldwide, navigating the complexities of manufacturing can be a daunting task, often involving multiple vendors, communication gaps, and costly delays. Samgo eliminates these hurdles by consolidating the entire process under one roof, ensuring quality, consistency, and a significantly accelerated time-to-market.

Phase 1: Collaborative Design and Engineering – Laying the Foundation for Success

The journey at Samgo begins not on the factory floor, but in the digital realm of design. The company’s philosophy is that a product’s manufacturability and cost are largely determined at the design stage.

“We believe in ‘Design for Manufacturability’ (DFM) from day one,” says Mr. Chen, Head of Engineering at Samgo. “By collaborating with our clients’ design teams early, we can identify potential issues, suggest material alternatives, and optimize the part geometry to ensure it is not only innovative but also practical and economical to produce in the millions.”

This phase involves:

Concept Consultation: Samgo’s engineers work with clients to understand the part's function, aesthetic requirements, and target cost.

3D CAD Model Analysis: Using advanced software, the team performs rigorous simulations to analyze mold flow, cooling time, and potential stress points.

DFM Report: A detailed report is provided, offering actionable recommendations on draft angles, wall thickness, rib design, and gate locations to prevent defects like warping or sink marks.

Phase 2: Precision Tooling – Crafting the Heart of Production

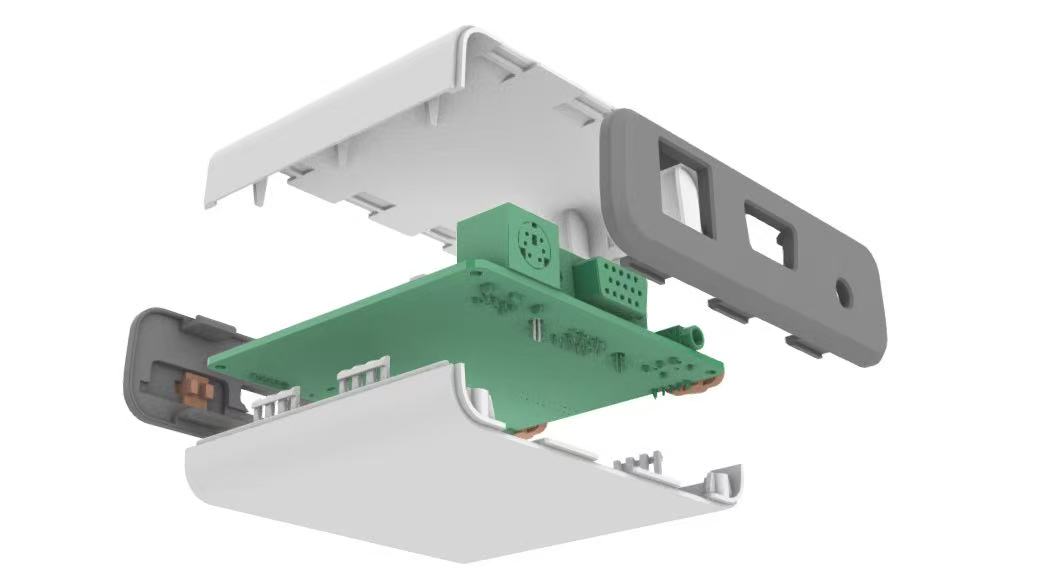

Once the design is finalized and optimized, the focus shifts to creating the mold—the custom-designed tool that will shape the molten plastic into the final part. Samgo’s tooling department is equipped with state-of-the-art CNC machining centers, EDM (Electrical Discharge Machining) equipment, and a team of highly skilled mold makers.

The tooling process is critical and involves several steps:

Mold Design: A detailed design of the multi-cavity mold is created, incorporating features for efficiency and longevity.

Precision Machining: High-grade tool steel is machined to micron-level tolerances to create the mold cores and cavities.

Assembly and Polishing: The mold components are meticulously assembled and polished to achieve the desired surface finish on the final plastic parts.

Trial and Validation: The first articles are produced from the new mold and subjected to rigorous inspection to ensure they meet all dimensional and aesthetic specifications.

Phase 3: Pilot Run and Validation – Ensuring Flawless Execution

Before committing to full-scale production, Samgo conducts a pilot run. This small-scale production batch serves as the final proving ground. The parts from this run are used for:

Dimensional and Functional Testing

Assembly Line Trials

Client Approval and Feedback

This step is a crucial risk-mitigation strategy, allowing for any final tweaks to the process or material before the significant investment of mass production begins.

Phase 4: High-Volume Mass Production and Assembly

With the mold perfected and the process validated, Samgo ramps up to full-scale mass production. The production floor is a showcase of modern manufacturing, featuring fully automated injection molding machines from 50 to 1000 tons.

Key features of Samgo’s production phase include:

In-Line Automation: Robotic arms are used for part extraction, sprue separation, and placement on conveyor belts for consistent quality and high output.

Real-Time Process Monitoring: The machines are equipped with IoT sensors that monitor critical parameters like pressure, temperature, and cycle time in real-time, ensuring every shot is identical to the last.

In-House Secondary Operations: To provide a true turnkey solution, Samgo offers a range of value-added services in-house, eliminating the need for clients to manage multiple suppliers.

The table below outlines Samgo's comprehensive secondary services:

| Service Category | Specific Processes Offered |

|---|---|

| Post-Processing | Trimming, degating, ultrasonic welding, vibration welding |

| Surface Finishing | Painting, pad printing, silk screening, electroplating |

| Assembly & Packaging | Manual and automated assembly, ultrasonic insertion of metal components, blister packing, shrink-wrapping |

| Quality Assurance | 100% inspection, batch sampling, CMM measurement, functional testing |

Uncompromising Quality Control: A Thread Through Every Phase

Quality control at Samgo is not a single department but a culture ingrained in every step. From the raw material certification to the final packaged product, a multi-tiered QC system is in place.

IQC (Incoming Quality Control): All raw materials are tested for properties like melt flow index and impact strength.

IPQC (In-Process Quality Control): Line operators and QC inspectors perform checks at every stage of production.

FQC (Final Quality Control): Finished batches are inspected against the client's approved sample before shipment.

Why Samgo Stands Out in the OEM Landscape

Samgo’s integrated approach offers tangible benefits that resonate with global clients:

| Traditional Multi-Vendor Model | Samgo's Integrated Model |

|---|---|

| Fragmented communication and responsibility | Single point of contact and accountability |

| Longer lead times due to vendor coordination | Streamlined process and faster time-to-market |

| Potential for quality inconsistencies between vendors | End-to-end quality control and consistency |

| Hidden costs in logistics and management | Transparent, all-inclusive costing |

| Design flaws discovered late, leading to expensive fixes | Early DFM involvement prevents costly errors |

“Our goal is to be more than just a supplier; we are a strategic manufacturing partner,” says the CEO of Samgo. “We empower our clients to focus on what they do best—marketing and selling their products—while we handle the complexities of production with unwavering reliability and precision.”

For businesses looking to launch a new plastic product or optimize an existing supply chain, Samgo presents a compelling solution that combines engineering expertise, manufacturing excellence, and a partnership-driven approach to turn visionary ideas into market-ready realities.