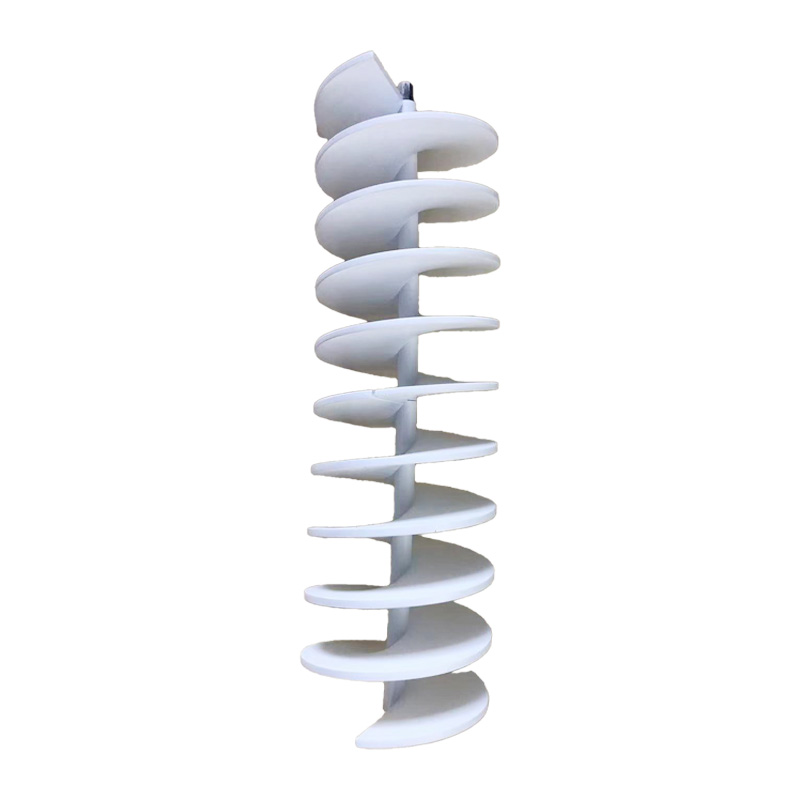

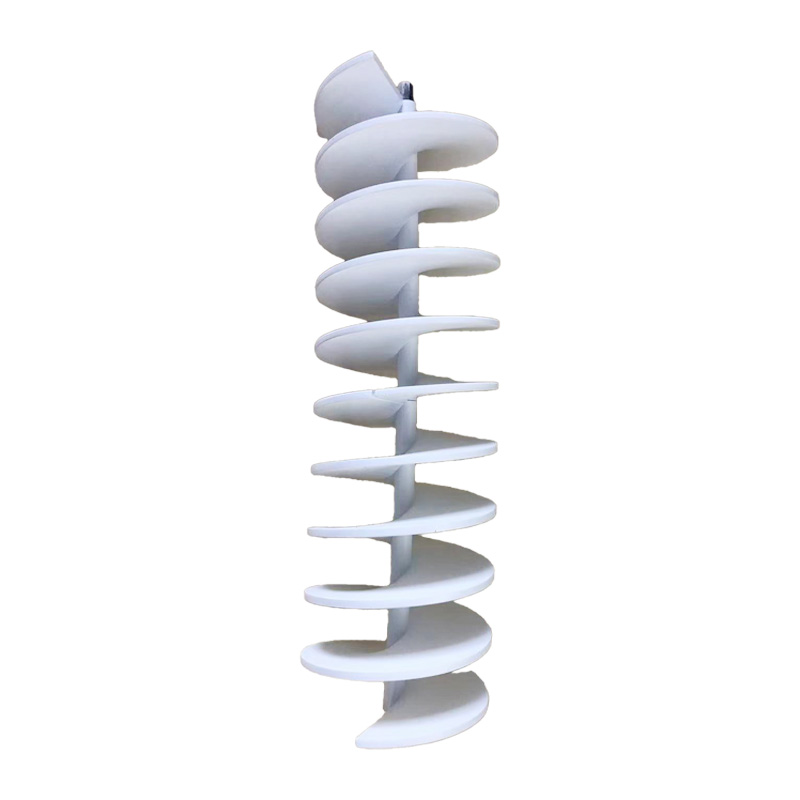

OEM service CNC prototype sample for outdoor gears

| Material | ABS, PC, Nylon, Metal etc | Model No | SMG-OEM-0002-B |

| OEM | Customized | Style | OEM |

| Origin | China | Package | customized |

| Size | Customized | Logo | customized |

good strength material

painting color

Part 1: Engineering Precision Meets Rugged Design – The Ultimate Pre-Production Validation Tool

Welcome to the future of product development for the serious outdoor innovator. Before you commit to mass production and stake your reputation on a new design, you deserve absolute certainty. Introducing our High-Fidelity CNC Machined Prototype – not just a model, but a critically precise, tangible incarnation of your vision, engineered to validate every nuance of your outdoor product under real-world conditions. This is where your CAD drawings transcend the digital realm and become a robust, functional artifact you can see, touch, stress-test, and perfect.

In the unforgiving world of outdoor gear—where a single flaw in a bracket, a miscalculation in a housing's tolerance, or a weakness in a mechanism can lead to catastrophic failure—compromise is not an option. Our prototyping service eliminates the guesswork. We utilize state-of-the-art 4-Axis and 5-Axis CNC machining centers to mill your designs from a solid block of premium material, delivering unmatched dimensional accuracy, exceptional structural integrity, and a surface finish that reveals the true ergonomics and aesthetics of your product. Unlike some 3D printing processes, CNC machining produces fully dense, isotropic parts with consistent mechanical properties in every direction, ensuring your stress analyses and functional checks are genuinely predictive of final injection-molded or machined production units.

This prototype is your product's first trial by fire. It’s designed to be subjected to the same forces it will face in the field. Test the impact resistance of a new action camera cage machined from PC. Assess the flex and recovery of a self-locking buckle carved from Nylon. Evaluate the heat dissipation of a metal flashlight body or the snap-fit assembly of an ABS component. By identifying and rectifying potential issues at this stage, you save immense amounts of time, capital, and resources, ultimately ensuring that when your product launches, it is synonymous with reliability, durability, and perfection. This isn't just a model; it's your most crucial investment in quality assurance and market success.

Part 2: Unmatched Specifications & Material Excellence – A Deep Dive into Quality

Our CNC machining process is meticulously calibrated to transform your complex 3D designs into reality with tolerances that leave no room for error. We understand that material selection is paramount, which is why we offer a curated selection of high-performance engineering materials to match your specific validation needs.

Key Specifications & Capabilities:

| Feature | Specification | Benefit for Your Outdoor Product |

|---|---|---|

| Available Materials | ABS, PC (Polycarbonate), Nylon (PA6/PA66), Aluminum 6061-T6, Stainless Steel 304/316 | A curated selection of the most relevant engineering plastics and metals for functional prototyping. Choose based on needed impact strength, stiffness, wear resistance, or corrosion resistance. |

| Dimensional Tolerance | ±0.005 inches (±0.127 mm) | Ensures critical components like threads, press-fits, and moving assemblies function perfectly, validating design fit before expensive production tooling is commissioned. |

| Surface Finish | Standard: As-Machined. Optional: Bead Blasting, Vapor Polishing (for ABS/PC), Anodizing (Metal), Powder Coating, Dyeing (Nylon) | The as-machined finish allows for critical inspection of tooling paths. Optional finishes like vapor polishing create a clear, injection-mold-like finish on plastics, while anodizing adds protection to metals. |

| Maximum Part Size | 300mm x 200mm x 150mm (11.8" x 7.9" x 5.9") | Accommodates a wide range of outdoor product components, from large knife handles and multi-tool bodies to complex mounting assemblies and sensor housings. |

| Machining Technology | 4-Axis & 5-Axis Simultaneous CNC Milling | Allows for the creation of highly complex, organic geometries and undercuts in a single setup, ensuring supreme accuracy for intricate designs without weak points from assembly. |

| File Format | STEP, IGES, SLDPRT, X_T (Parasolid), 3DM (Rhino) | We work with all major CAD formats to ensure a seamless transition from your design environment to our machining floor. |

| Lead Time | 5-7 Business Days (After Design Review) | Get your functional prototype in hand quickly, accelerating your development cycle and time-to-market. |

Material Selection Guide:

ABS (Acrylonitrile Butadiene Styrene): The ideal choice for prototypes that must mimic the final production material for many consumer goods. Excellent for form, fit, and function testing of housings, casings, and consumer components. It offers good impact resistance, rigidity, and can be easily sanded, glued, and painted. It is also a candidate for vapor polishing to achieve a glossy, production-like finish.

PC (Polycarbonate): The undisputed champion of impact resistance and transparency. Choose PC for prototypes that require ultimate toughness, such as protective cases, lens covers, transparent housings, or components that will undergo high-stress impact testing. It has high strength and stiffness and can be made optically clear.

Nylon (Polyamide - PA6/PA66): The best choice for parts requiring high wear resistance, low friction, and excellent chemical resistance. It is a tough, durable, and slightly flexible material. Ideal for functional testing of gears, buckles, clips, hinges, and other moving parts that need to withstand repeated use and abrasion. It can be dyed black or other colors.

Aluminum 6061-T6: The standard for high-strength, lightweight metal prototypes. Offers an excellent strength-to-weight ratio, good machinability, and decent corrosion resistance. Perfect for structural components, brackets, heat sinks, drone armatures, and high-end consumer product housings. It can be anodized for surface hardening and color.

Stainless Steel 304/316: Used when ultimate strength, corrosion resistance, and durability are non-negotiable. Essential for prototypes that will be used in marine or corrosive environments, for extreme load-bearing applications, or for components like custom fasteners, surgical tools, or diving equipment. 316 offers superior corrosion resistance to 304.

The Process: From File to Finished Prototype:

Design Consultation & DFM Analysis: Our engineers review your 3D model and material selection, providing a Design for Manufacturability (DFM) report. We highlight potential machining challenges and suggest optimizations for cost and strength.

Precision Machining: Your approved design is programmed into our CNC mills. A solid billet of your chosen material is precisely carved away with cutting tools following paths accurate to within microns.

Deburring & Quality Inspection: The part is meticulously hand-finished. It then undergoes a rigorous quality inspection against your drawing specifications.

Optional Post-Processing: If selected, the part undergoes its chosen finishing process (e.g., vapor polishing for PC, anodizing for Aluminum).

Swift Delivery: Your completed, high-precision prototype is carefully packaged and shipped directly to you, ready for testing.

Part 3: The Indispensable Advantage for Outdoor Brands & Designers

Purchasing this CNC machined prototype is the definitive step between a theoretical design and a market-ready product. It is an indispensable tool for designers, engineers, startup founders, and established brands who refuse to compromise on quality.

Applications in the Outdoor Industry:

Functional & Durability Testing: Validate the strength of a Nylon trekking pole buckle, the impact resistance of a PC-based GPS unit casing, the corrosion resistance of a stainless steel marine snap shackle, or the fatigue life of an aluminum bike derailleur component.

Ergonomic Validation: There is no substitute for holding a physically accurate model. Test the grip on a tool handle machined from ABS, the button placement on a metal flashlight, or the strap contour on a headlamp. Gather invaluable user feedback before finalizing designs.

Fit and Assembly Check: Assemble your product with off-the-shelf or custom components. Verify that everything fits together seamlessly between metal and plastic parts, avoiding costly retooling fees down the line.

Marketing & Sales Assets: A high-quality CNC machined prototype, especially in a finished material like anodized aluminum or vapor-polished PC, serves as a stunning visual aid for crowdfunding campaigns, investor presentations, and early marketing material. It demonstrates professionalism and a commitment to quality.

Manufacturing Reference: This prototype acts as a perfect "golden sample" for your manufacturing partner, clearly communicating design intent, quality expectations, and final approval.

By holding our CNC machined prototype in your hands, you are making a data-driven decision. You are confirming that your design is not just viable, but exceptional. You are ensuring that your product, built for adventure, is born from a process of rigor and precision.

Ordering is simple: Upload your CAD file, select your preferred material and finishing options, and receive an instant quote. Our technical team is ready to advise on the best material choice for your specific application. Build with confidence. Build with precision. Launch without doubt.

What exactly are your OEM services?

Our OEM (Original Equipment Manufacturing) service allows you to bring your unique outdoor gear ideas to life. We handle the entire product development and manufacturing process based on your specifications, designs, and brand requirements. From initial concept and material sourcing to prototyping, production, and quality control, we become your dedicated manufacturing partner. Your brand logo and identity will be applied to the final products.What is your MOQ (Minimum Order Quantity)?

We understand that brands need flexibility, especially when launching new products. Therefore, we offer flexible MOQs, which vary depending on the product complexity, materials required, and customization level. We encourage you to discuss your project with us, and we will do our best to propose a feasible MOQ.Can you help us develop a product from just an idea or a sketch?

Absolutely! We specialize in turning concepts into high-quality, market-ready products. Our product development team will work closely with you to refine your idea, select appropriate materials, create technical drawings, and develop prototypes until your vision is perfectly realized.What are the typical steps in the OEM process with your company?

1.Initial Inquiry & Consultation: You share your concept, target market, and requirements. 2.Quotation & Agreement: We provide a detailed quotation, and once approved, we sign a service agreement. 3.Research & Development (R&D): Our team works on technical designs, material selection, and sample development. 4.Prototyping: We create a physical prototype for your evaluation and feedback. 5. Molds:After design confirming, we will creat mold before production. 5.Sample Approval: You approve the final sample, confirming quality, design, and functionality. 6.Mass Production: Upon your production order confirmation, we begin manufacturing your products. 7.Rigorous Quality Control (QC): We conduct inspections throughout production and a final random inspection before shipment. 8.Shipping & Delivery: We securely pack and arrange shipment to your designated destination.How long does the entire process take from concept to delivery?

The timeline varies significantly based on product complexity and order quantity. A general estimate is: Development & Sampling: 4-8 weeks. Mass Production: 4-6 weeks after sample approval. Please note that this is an estimate, and a precise timeline will be provided with your project quotation.Who owns the intellectual property (IP) and mold/tooling for the custom products?

You retain 100% ownership of your brand identity, designs, and product IP. For any custom molds or tooling created specifically for your project, ownership can be transferred to you upon agreement. We strictly adhere to confidentiality and will never use your designs for other clients.How do you determine the price for an OEM order?

The unit price is determined by several factors, including: Product complexity and design Cost of raw materials Labor and manufacturing processes involved Order quantity Packaging requirements We strive to offer competitive pricing without compromising on quality.What is your quality control process?

Quality is our top priority. Our QC process includes: Incoming Quality Control (IQC): Inspection of all raw materials. In-Process Quality Control (IPQC): Checks during key stages of production. Pre-Shipment Inspection (PSI): A final random inspection of finished products against your approved sample and our quality standards. We can provide detailed QC reports.Can we inspect the products before they are shipped?

Yes. We highly recommend a pre-shipment inspection. You are welcome to send your own QC inspector, or you can hire a third-party inspection company to perform the check at our factory. We can also provide you with photos and videos of the production and final products.How do you handle shipping?

We have extensive experience in shipping outdoor gear globally. We can handle the logistics for you and arrange shipment via sea (for large volumes) or air (for smaller, urgent orders). We work with reliable freight forwarders to ensure a smooth process. Shipping costs will be included in your final quotation.

Related Products