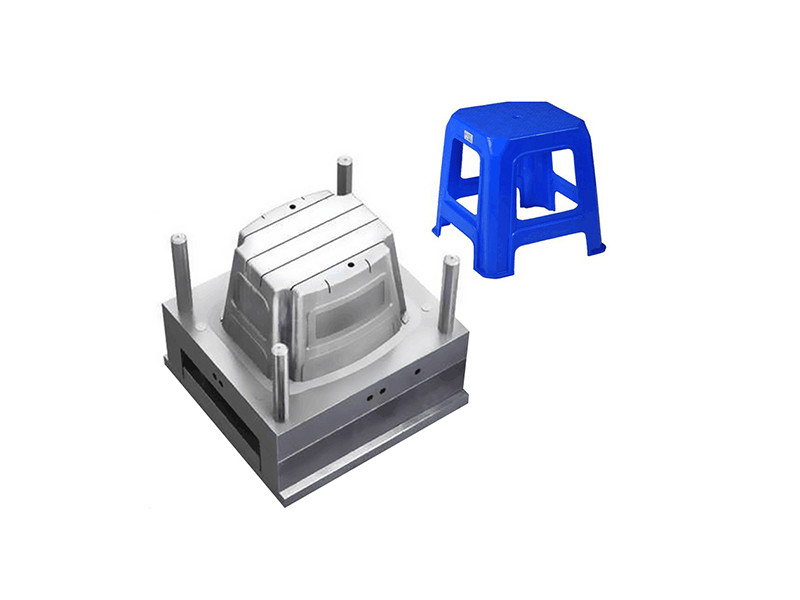

New style Custom Plastic Stools

Craft Your Vision: The Ultimate Guide to Custom Plastic Stools

Introduction: More Than a Stool, It's Your Brand's Signature

In today's competitive landscape, every detail counts. A custom plastic stool is not just seating; it's a powerful touchpoint that communicates your brand's identity, values, and attention to quality. Our bespoke plastic stool service transforms your vision into a tangible, durable, and beautifully designed asset. From concept to creation, we partner with you to craft stools that enhance user experience, optimize space, and tell your unique story.

1. Your Design, Realized: Endless Customization Possibilities

Unleash your creativity with our comprehensive customization options. We provide the canvas; you create the masterpiece.

Customization Options Table

| Customization Aspect | Available Options | Ideal For |

|---|---|---|

| Color & Finish | Full Pantone spectrum, transparent tints, marble effects, UV-resistant pigments. | Brand alignment, creating specific atmospheres (e.g., calm blues for spas, vibrant yellows for schools). |

| Logo & Graphics | In-mold labeling, silk-screen printing, debossing, full-color digital prints. | Maximizing brand visibility, promotional events, corporate gifts. |

| Shape & Ergonomics | Contoured seats, varied backrest designs (low, mid, high), integrated armrests. | Enhancing comfort for long-term seating (e.g., bars, auditoriums), creating a unique silhouette. |

| Material & Texture | Polypropylene (PP), Polyethylene (PE), recycled materials, anti-slip textures, wood-grain finishes. | Matching specific durability needs (indoor/outdoor), achieving a particular aesthetic feel. |

| Functional Add-ons | Stacking lips, ganging attachments, flip-up seats, cushioned tops. | Space-saving in multi-purpose halls, creating connected rows for events, adding comfort. |

2. Engineered for Excellence: Unmatched Quality & Durability

A beautiful design must be backed by robust engineering. Our stools are built to withstand the test of time and use.

Quality & Durability Features Table

| Feature | Component | Benefit to You |

|---|---|---|

| High-Impact Material | Premium, UV-stabilized Polypropylene (PP). | Resists cracking, fading, and impact damage, ensuring a long lifespan even with heavy use. |

| Reinforced Structure | Ribbed under-seat design and thick leg walls. | Superior weight capacity (tested up to 150kg/330lbs), prevents flexing and breakage. |

| Stable Geometry | Wide, splayed legs and a balanced stance. | Excellent stability and tip-resistance, ensuring user safety on various floor types. |

| Easy Maintenance | Non-porous, smooth surface (optional). | Simply wipes clean with a damp cloth, ideal for hygienic environments like kitchens and hospitals. |

3. Smart & Sustainable: Designed for the Modern World

We believe that great design is also responsible design. Our customization process integrates smart features that benefit both your operations and the planet.

Space-Saving Stackability: Our stools are engineered to stack securely and compactly. This means you can store hundreds of stools in a minimal footprint, freeing up valuable floor space for other uses. Perfect for venues that need to quickly reconfigure their layout.

Effortless Portability & Storage: Lightweight yet strong, our stools are easy to move and handle. The integrated stacking lips and handles (optional) make transport a one-person job, reducing labor effort and time.

Eco-Conscious Manufacturing: We are committed to sustainability. We offer material options that incorporate post-consumer recycled (PCR) content and ensure our products are 100% recyclable at the end of their long life, helping you reduce your environmental footprint.

4. Our Collaborative Customization Process

We make the journey from idea to product seamless and transparent.

Consultation & Vision: We start by listening. Share your ideas, brand guidelines, and functional requirements.

Design & Quotation: Our experts provide a free DFM (Design for Manufacturability) analysis and a detailed 3D render of your custom stool, along with a transparent quote.

Prototyping & Approval: We create a physical prototype for your evaluation, ensuring every detail—color, finish, feel—meets your expectation.

Production & Delivery: Upon your approval, we move to mass production with strict quality control, followed by reliable, on-time delivery to your doorstep.

Conclusion: Elevate Your Space with Custom Seating

Don't settle for generic. A custom plastic stool is a cost-effective, high-impact solution to reinforce your brand, enhance functionality, and demonstrate your commitment to quality. It’s an investment that pays dividends in comfort, aesthetics, and operational efficiency every single day.

Ready to create your signature stool? Contact our customization specialists today for a free, no-obligation consultation and quote!

What exactly are your OEM services?

Our OEM (Original Equipment Manufacturing) service allows you to bring your unique outdoor gear ideas to life. We handle the entire product development and manufacturing process based on your specifications, designs, and brand requirements. From initial concept and material sourcing to prototyping, production, and quality control, we become your dedicated manufacturing partner. Your brand logo and identity will be applied to the final products.What is your MOQ (Minimum Order Quantity)?

We understand that brands need flexibility, especially when launching new products. Therefore, we offer flexible MOQs, which vary depending on the product complexity, materials required, and customization level. We encourage you to discuss your project with us, and we will do our best to propose a feasible MOQ.Can you help us develop a product from just an idea or a sketch?

Absolutely! We specialize in turning concepts into high-quality, market-ready products. Our product development team will work closely with you to refine your idea, select appropriate materials, create technical drawings, and develop prototypes until your vision is perfectly realized.What are the typical steps in the OEM process with your company?

1.Initial Inquiry & Consultation: You share your concept, target market, and requirements. 2.Quotation & Agreement: We provide a detailed quotation, and once approved, we sign a service agreement. 3.Research & Development (R&D): Our team works on technical designs, material selection, and sample development. 4.Prototyping: We create a physical prototype for your evaluation and feedback. 5. Molds:After design confirming, we will creat mold before production. 5.Sample Approval: You approve the final sample, confirming quality, design, and functionality. 6.Mass Production: Upon your production order confirmation, we begin manufacturing your products. 7.Rigorous Quality Control (QC): We conduct inspections throughout production and a final random inspection before shipment. 8.Shipping & Delivery: We securely pack and arrange shipment to your designated destination.How long does the entire process take from concept to delivery?

The timeline varies significantly based on product complexity and order quantity. A general estimate is: Development & Sampling: 4-8 weeks. Mass Production: 4-6 weeks after sample approval. Please note that this is an estimate, and a precise timeline will be provided with your project quotation.Who owns the intellectual property (IP) and mold/tooling for the custom products?

You retain 100% ownership of your brand identity, designs, and product IP. For any custom molds or tooling created specifically for your project, ownership can be transferred to you upon agreement. We strictly adhere to confidentiality and will never use your designs for other clients.How do you determine the price for an OEM order?

The unit price is determined by several factors, including: Product complexity and design Cost of raw materials Labor and manufacturing processes involved Order quantity Packaging requirements We strive to offer competitive pricing without compromising on quality.What is your quality control process?

Quality is our top priority. Our QC process includes: Incoming Quality Control (IQC): Inspection of all raw materials. In-Process Quality Control (IPQC): Checks during key stages of production. Pre-Shipment Inspection (PSI): A final random inspection of finished products against your approved sample and our quality standards. We can provide detailed QC reports.Can we inspect the products before they are shipped?

Yes. We highly recommend a pre-shipment inspection. You are welcome to send your own QC inspector, or you can hire a third-party inspection company to perform the check at our factory. We can also provide you with photos and videos of the production and final products.How do you handle shipping?

We have extensive experience in shipping outdoor gear globally. We can handle the logistics for you and arrange shipment via sea (for large volumes) or air (for smaller, urgent orders). We work with reliable freight forwarders to ensure a smooth process. Shipping costs will be included in your final quotation.

Related Products