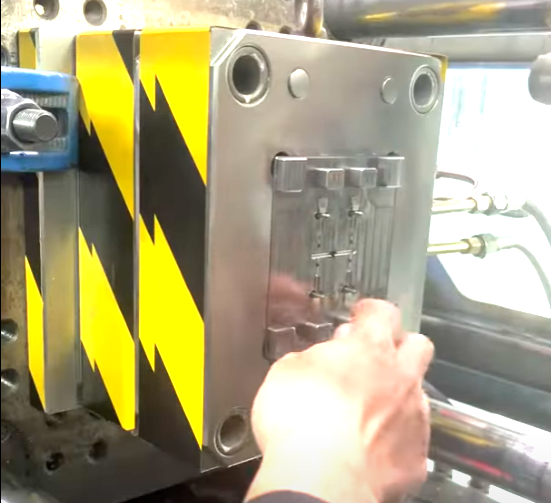

Proper installation of nylon injection molds ensures optimal performance and extended service life. Begin by thoroughly cleaning the mold surface and platens. Preheat the mold to 60-80°C to accommodate nylon's thermal characteristics. Carefully align the mold with the machine platens using alignment rings, ensuring perfect parallelism.

During installation:

Apply high-temperature anti-seize lubricant to guide pins and moving components

Set initial clamping force to 3-5 tons per square inch of projected area

Establish cooling channels with 20-30°C water temperature

Configure nozzle temperature at 240-280°C based on nylon grade

Our technical team recommends:

Maintaining consistent mold temperature within ±5°C

Implementing a progressive injection speed profile

Setting pack pressure at 60-80% of injection pressure

Conducting trial shots with short shots to verify filling balance

Contact our engineering specialists for customized parameter optimization and professional mold maintenance services.