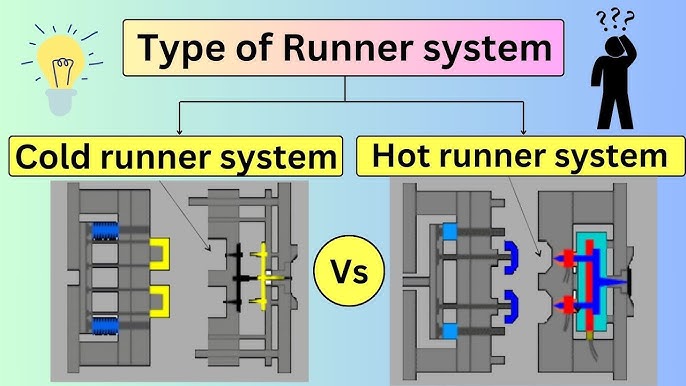

Cold Runner Systems: The traditional approach.

How it works: Unheated channels solidify with each cycle, creating a runner that must be separated and recycled.

Pros: Lower mold cost, better for heat-sensitive materials, easier color changes.

Cons: High material waste, slower cycle times, added cost for recycling runners.

Hot Runner Systems: The advanced, modern approach.

How it works: A heated manifold keeps plastic molten in the channels, injecting it directly into cavities with no solid runner.

Pros: Eliminates material waste, faster cycle times, superior part quality and aesthetics.

Cons: Higher initial mold cost, more complex process control, difficult color changes.

202512-01Cold Runner Systems: The traditional approach. How it works: Unheated channels solidify with each cycle, creating a runner that must be separated and recycled. Pros: Lower mold cost, better for heat-sensitive materials, easier color changes. Cons: High material waste, slower cycle times, added cost for recycling runners. Hot Runner Systems: The advanced, modern approach. How it works: A heated manifold keeps plastic molten in the channels, injecting it directly into cavities with no solid runner. Pros: Eliminates material waste, faster cycle times, superior part quality and aesthetics. Cons: Higher initial mold cost, more complex process control, difficult color changes.

202512-01Cold Runner Systems: The traditional approach. How it works: Unheated channels solidify with each cycle, creating a runner that must be separated and recycled. Pros: Lower mold cost, better for heat-sensitive materials, easier color changes. Cons: High material waste, slower cycle times, added cost for recycling runners. Hot Runner Systems: The advanced, modern approach. How it works: A heated manifold keeps plastic molten in the channels, injecting it directly into cavities with no solid runner. Pros: Eliminates material waste, faster cycle times, superior part quality and aesthetics. Cons: Higher initial mold cost, more complex process control, difficult color changes.