Custom LED Light Housing

1.Precision Thermal Management: Expertly engineered with advanced cooling fins and thermal pads to effectively dissipate heat, significantly extending LED lifespan and performance.

2.Superior Protection (IP68): Offers excellent defense against dust, moisture, and corrosion, ensuring reliable operation in demanding indoor and outdoor environments.

3.High-Grade, Durable Materials: Constructed from robust materials like die-cast aluminum or engineering plastics, providing exceptional strength, durability, and a lightweight design.

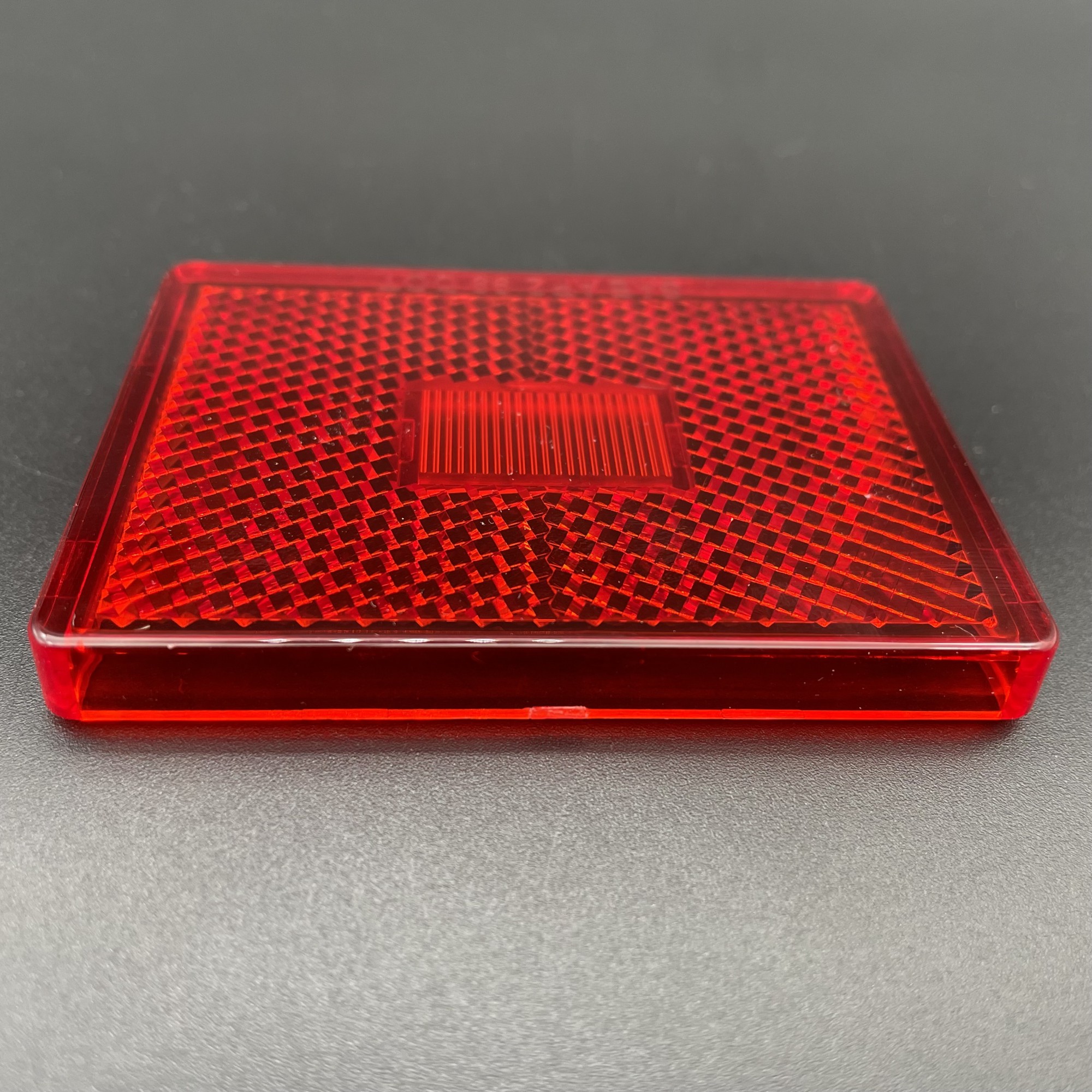

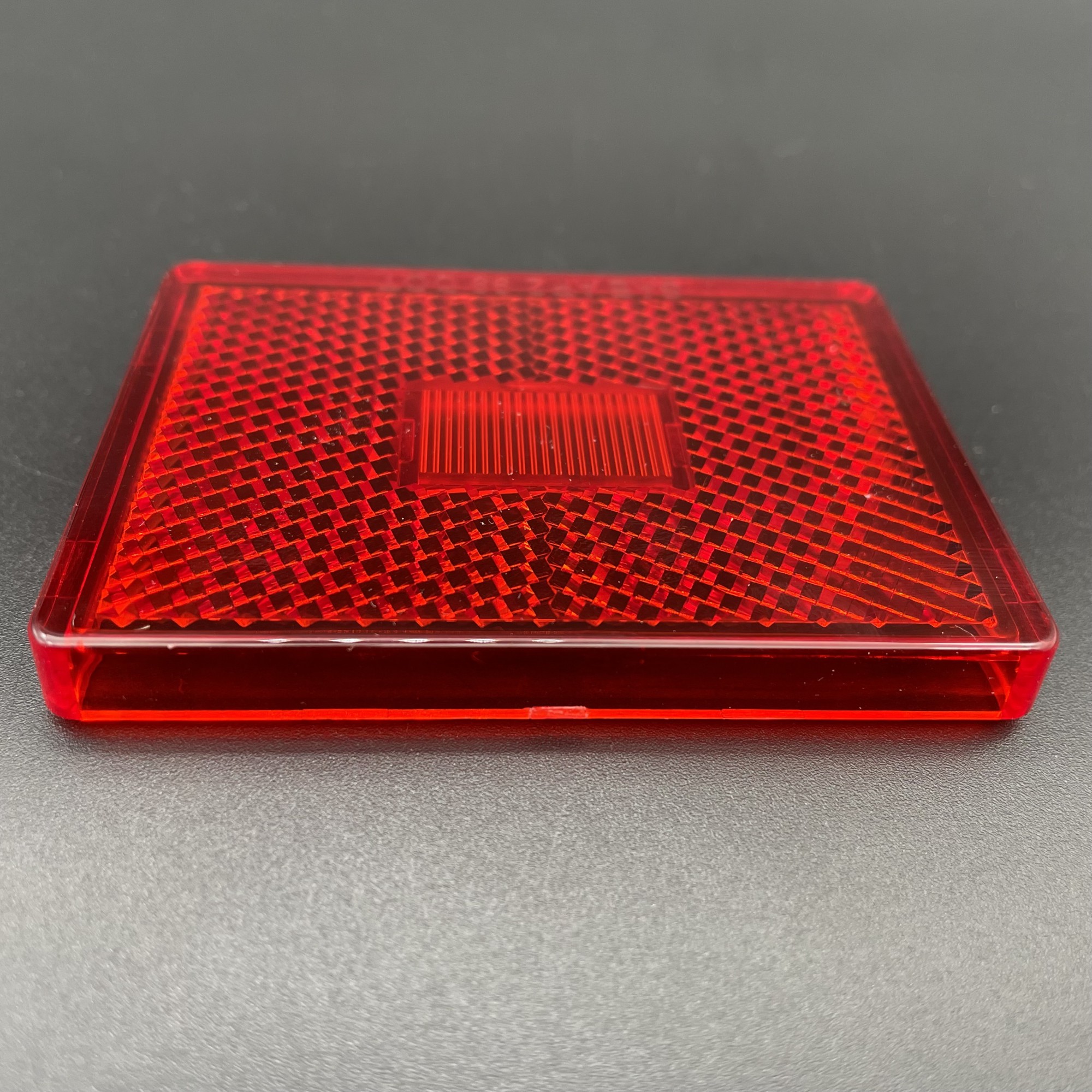

4.Tailored Aesthetic & Optical Design: Fully customizable shapes, colors, and textures to meet specific brand and design needs, with optimized light distribution for superior illumination.

5.Streamlined Integration: Features a user-centric design for easy assembly and installation, reducing labor time and cost while ensuring a secure fit for all components.

Custom LED Light Housings: Engineered for Performance, Designed for Vision

Elevate your lighting solutions from ordinary to exceptional. Our custom LED light housings are more than just protective shells; they are the critical foundation for performance, longevity, and aesthetic appeal. We partner with you to design and manufacture housings that seamlessly integrate into your application, ensuring your LED products shine brighter and last longer.

Why a Custom Housing is Your Competitive Edge

In the competitive LED market, the housing is what transforms a collection of electronic components into a reliable, high-performance product. Off-the-shelf solutions often lead to compromises in thermal management, design, and durability. Our custom approach ensures:

Perfect Fit for Your Electronics: Tailored internal structures securely hold PCBs, drivers, and connectors, eliminating vibration damage and ensuring perfect optical alignment.

Brand Identity and Aesthetics: The housing is the face of your product. We create unique forms, colors, and finishes that reinforce your brand and stand out in the market.

Application-Specific Engineering: Whether it's for harsh outdoor environments, sterile medical settings, or modern architectural spaces, we engineer the housing to meet the exact demands of its use case.

Key Product Highlights & Innovations

Our design and manufacturing process incorporates cutting-edge innovations to deliver unparalleled value.

Advanced Thermal Management: This is our core expertise. We integrate extensive cooling fins, thermal pads, and use materials like die-cast aluminum with high thermal conductivity to actively draw heat away from the LED chips, preventing lumen depreciation and extending lifespan by up to 50%.

Uncompromising Superior Protection (IP68 Rated): Engineered to be your product's first line of defense. Our housings provide complete protection against dust, water, and corrosive elements, guaranteeing reliable performance in the most demanding indoor and outdoor applications.

High-Grade, Application-Tailored Materials: We don't believe in a one-size-fits-all material choice. We select from a range of robust options—from lightweight, corrosion-resistant die-cast aluminum to high-strength, UV-stabilized engineering plastics—to perfectly balance durability, weight, and cost.

Optimized Optical & Aesthetic Design: The housing shape is integral to light distribution and visual appeal. We design for perfect beam control and offer limitless customization in shape, color, texture, and finish to match your exact design vision.

Streamlined Assembly & Integration: A housing should be easy to work with. Our designs feature intuitive snap-fits, accessible mounting points, and clear cable management pathways to significantly reduce assembly time and cost on your production line.

Technical Specifications at a Glance

The table below summarizes the core technical capabilities and material options for our custom LED housings.

| Category | Specification Options | Description & Benefit |

|---|---|---|

| Primary Materials | Die-Cast Aluminum (ADC-12), Aluminum Alloy (6063), Polycarbonate (PC), ABS/PC Blend | Aluminum for superior heat dissipation; Engineering Plastics for cost-effectiveness and complex shapes. |

| IP Protection Rating | IP65, IP66, IP68 (Submersible) | Certified protection levels for dust and water ingress, ensuring suitability for various environments. |

| Thermal Management | Integrated Fins, Thermal Interface Pads, Conductive Structural Design | Maximizes surface area for passive cooling, maintaining optimal LED junction temperature. |

| Surface Finishes | Powder Coating, Anodizing (Matte/Gloss), Brushed, Painted | Enhances corrosion resistance and provides a wide range of aesthetic choices to match your design. |

| Customization | Full Custom Geometry, Color Matching, Brand Logos, Integrated Mounts | Complete freedom to create a housing that is uniquely yours, both functionally and visually. |

| Compliance | RoHS, REACH, UL/CE Standards (Material Dependent) | Our materials and processes adhere to international safety and environmental standards. |

Ideal Applications Across Industries

Our custom LED housings are engineered for success across a diverse range of sectors:

Architectural & Commercial Lighting: Sleek, minimalist housings for downlights, track lights, and linear fixtures in offices, retail spaces, and hotels.

Industrial & High-Bay Lighting: Robust, high-IP-rated housings that withstand dust, moisture, and vibration in factories and warehouses.

Outdoor & Street Lighting: Durable, weatherproof housings for street lamps, floodlights, and landscape lighting, designed for decades of service.

Automotive & Transportation: High-strength, thermally efficient housings for headlights, taillights, and interior vehicle lighting.

Specialty & Consumer Appliances: Custom-shaped housings that integrate perfectly into consumer products, from smart home devices to appliances.

Our Collaborative Customization Process

We make the journey from concept to production seamless and transparent.

Consultation & DFM Analysis: We start by understanding your needs and performing a thorough Design for Manufacturability (DFM) analysis on your initial designs.

Prototyping & Validation: We create high-fidelity prototypes for your team to test for fit, form, function, and thermal performance.

Refinement & Production: We refine the design based on your feedback and then move into full-scale production using precision techniques like injection molding and die-casting.

Lifetime Support: Our partnership continues after delivery with dedicated technical support and guidance.

Invest in a Foundation of Quality

Your LED technology deserves a housing that matches its potential. By choosing our custom LED light housings, you are not just buying a component—you are investing in the reliability, performance, and market success of your final product.

Contact our engineering team today for a free, no-obligation project consultation and quotation. Let's collaborate to build the perfect foundation for your light.